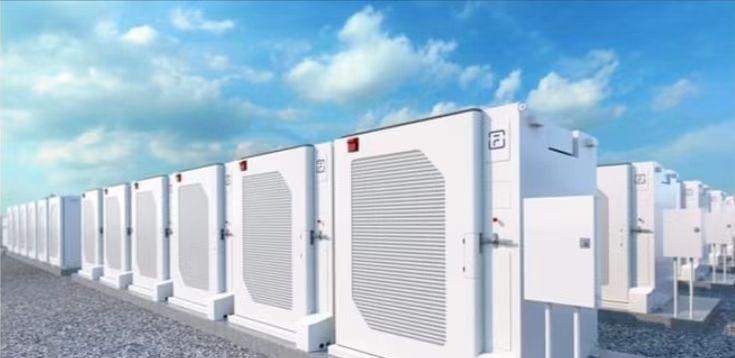

The global demand for energy storage and renewable energy systems continues to rise sharply. Utility companies, EPC contractors, and industrial buyers are investing heavily in battery energy storage systems (BESS) to stabilize grids, integrate renewables, and cut energy costs.

But behind every BESS project lies a critical challenge: the volatile pricing of raw materials. From lithium to cobalt, graphite to vanadium, raw material price fluctuations directly affect system costs, procurement timelines, and long-term investment strategies.

For buyers, understanding these dynamics is essential for making informed decisions. This article explains what drives raw material price changes, how they impact the energy storage industry, and what buyers should consider when planning purchases.

Why Raw Material Prices Matter in Energy Storage

Battery technologies are built on a foundation of critical raw materials:

- Lithium: Core element for lithium-ion batteries (LFP, NMC, NCA).

- Cobalt: Used in NMC/NCA chemistries for stability and performance.

- Nickel: Provides higher energy density in advanced lithium-ion chemistries.

- Graphite: Essential for anodes in most lithium-ion cells.

- Vanadium: Key material for vanadium redox flow batteries.

Fluctuations in these materials influence:

- CapEx of energy storage projects

- Payback period and ROI

- Supplier pricing and procurement negotiations

- Technology selection (e.g., LFP vs. NMC, lithium-ion vs. flow battery)

Key Drivers of Raw Material Price Fluctuations

1. Supply and Demand Imbalance

- Lithium demand has surged with the rise of EVs and grid-scale storage. Supply often lags, causing sharp price increases.

- Cobalt supply is highly concentrated in the Democratic Republic of Congo (DRC), leading to political and supply chain risks.

2. Geopolitical and Trade Policies

- Export restrictions, tariffs, and trade disputes (e.g., China vs. U.S. technology tensions) impact availability and cost.

- Resource nationalism in countries rich in lithium, cobalt, or nickel adds unpredictability.

3. Energy Transition Acceleration

- Global commitments to carbon neutrality drive demand for both EV batteries and stationary storage, straining supply chains.

4. Mining and Processing Costs

- High energy prices, labor issues, or stricter environmental regulations raise costs of extraction and refining.

5. Currency Exchange Rates

- Commodities are priced in USD. Buyers in Europe, Asia, and Africa face cost shifts depending on currency fluctuations.

Historical Examples of Price Volatility

- Lithium carbonate prices quadrupled between 2020 and 2022 due to EV boom demand.

- Cobalt prices spiked in 2018, then fell sharply in 2019 as oversupply met weaker demand.

- Vanadium prices surged in 2017–2018 due to Chinese steel regulation changes, directly impacting flow battery costs.

These swings can significantly alter project economics within months.

How Raw Material Prices Impact Buyers

1. Total Cost of Ownership (TCO)

If raw material prices rise, system CapEx increases. This may delay project ROI and extend the payback period.

2. Contract Negotiations with Suppliers

- Suppliers often adjust quotes every few months based on commodity market conditions.

- Buyers may face “validity periods” of only 30–60 days on quotes.

3. Technology Choice

- High cobalt prices push buyers toward LFP batteries, which avoid cobalt and nickel.

- Rising vanadium costs may slow flow battery adoption compared to lithium-ion.

4. Procurement Timing

- Buyers who lock contracts during price spikes may overpay compared to waiting for market corrections.

5. Long-Term Planning

- Large projects (50MWh+) require stable cost forecasts. Price volatility complicates financing and investor confidence.

What Buyers Can Do to Manage Risk

1. Diversify Technology Options

Evaluate multiple chemistries:

- LFP (Lithium Iron Phosphate): No cobalt/nickel, stable costs, safer for C&I and utility projects.

- NMC (Nickel Manganese Cobalt): Higher energy density, but more exposed to cobalt/nickel price swings.

- Vanadium Flow Batteries: Long lifetime, but sensitive to vanadium market fluctuations.

2. Secure Long-Term Supply Contracts

- Negotiate fixed-price or indexed contracts with suppliers to stabilize costs.

- Work with suppliers that have direct partnerships with mining or refining companies.

3. Monitor Market Trends

- Follow commodity indexes for lithium, cobalt, and nickel.

- Track government policies on resource exports and subsidies.

4. Consider Recycling and Second-Life Solutions

- Battery recycling can reduce dependency on volatile raw material markets.

- Second-life EV batteries may provide cost-effective stationary storage options.

5. Collaborate with Experienced Suppliers

Choose partners who can:

- Provide transparent cost breakdowns.

- Offer alternative chemistries when raw material prices spike.

- Share regular market updates to help buyers make informed decisions.

How Suppliers Can Build Trust with Buyers

Suppliers should not just pass price volatility onto buyers—they should help them navigate uncertainty. Best practices include:

- Publishing LinkedIn posts explaining raw material price trends.

- Offering TCO models that account for possible price swings.

- Sharing technology comparison charts (LFP vs. NMC vs. flow battery).

- Highlighting recycling initiatives to reduce long-term cost risks.

This proactive communication builds buyer confidence even in volatile markets.

In the energy storage, renewable energy, and BESS industry, raw material price fluctuations are inevitable. Lithium, cobalt, nickel, graphite, and vanadium markets will continue to experience volatility as demand surges worldwide.

For buyers, the key is not to fear these fluctuations—but to understand, plan, and manage them. By diversifying technologies, securing long-term contracts, and working with transparent suppliers, buyers can protect their investments and ensure project success.

In a competitive global market, those who master raw material risk management will be best positioned to build cost-effective, reliable, and scalable energy storage solutions.