Selecting the right hybrid inverter size is one of the most critical decisions in designing a solar + battery energy storage system (ESS).

For installers, distributors, and system designers, proper inverter sizing ensures reliability, efficiency, and safety, while preventing costly system failures or warranty disputes.

This article provides a practical, step-by-step guide to sizing a hybrid inverter based on load requirements, battery capacity, and PV array size, with examples drawn from residential and small commercial energy storage projects.

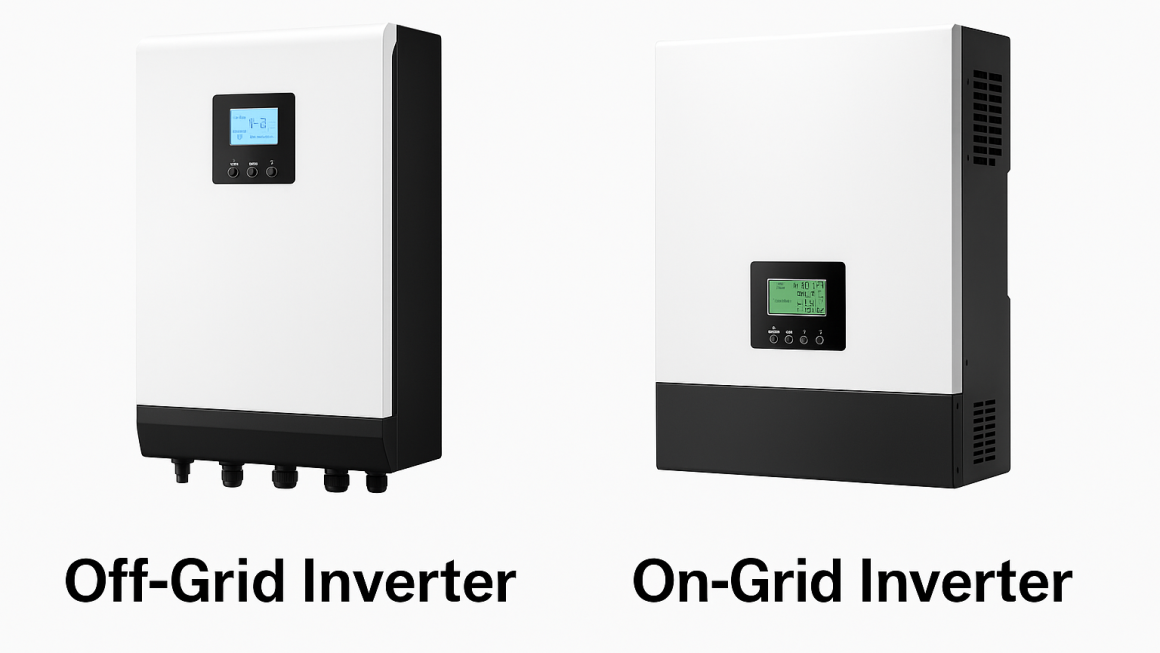

1. What Does a Hybrid Inverter Do?

A hybrid inverter combines the functions of:

- Solar inverter – converting DC power from PV panels to AC power.

- Battery inverter – charging/discharging the energy storage system.

- Grid interface – managing energy flow between solar, battery, load, and grid.

In simple terms, it’s the “brain” of your PV + storage system, deciding:

- When to use solar power directly,

- When to charge or discharge the battery,

- And when to draw or export power from/to the grid.

Because it manages multiple power sources, proper sizing is essential to ensure smooth operation and to prevent overloading or underutilization.

2. The Three Inputs That Define Sizing

To correctly size a hybrid inverter, you must analyze three aspects:

- Load demand (AC side)

- What is the total load the inverter must supply?

- What is the peak power (instantaneous maximum)?

- What is the continuous running power?

- Battery configuration (DC side)

- What is the nominal voltage (e.g., 48V or 51.2V)?

- What is the capacity (Ah or kWh)?

- What is the maximum discharge current supported by the BMS?

- Solar PV array (DC input)

- What is the total PV array power (kWp)?

- What are the string voltages, MPPT ranges, and currents?

These three must match the hybrid inverter’s technical limits to ensure stable operation and long life.

3. Step 1: Start from the Load

Your load determines the inverter output power rating.

Example – Residential:

| Load Type | Power (W) | Quantity | Total (W) |

|---|---|---|---|

| Refrigerator | 200 | 1 | 200 |

| Lights | 20 | 10 | 200 |

| Fans | 60 | 3 | 180 |

| TV | 100 | 1 | 100 |

| Water Pump | 800 | 1 | 800 |

| Total Running Load | 1,480 W (~1.5 kW) | ||

| Peak Load (Starting) | ≈ 3.0 kW |

Here, the continuous load is 1.5 kW, but the starting surge (due to motors and compressors) can reach 3 kW.

✅ Recommended inverter rating: 3–3.6 kW hybrid inverter for safety margin.

Example – Small Commercial:

For a 10 kW continuous load (air conditioners, lighting, IT equipment), with peak surges of 15 kW, choose a 15–20 kW hybrid inverter.

⚙️ Rule of thumb:

Inverter AC power ≥ 1.3 × average load power

This ensures stable operation and room for transient peaks.

4. Step 2: Match the Battery Bank

The battery bank determines how much power can be drawn on the DC side and for how long.

(1) Voltage Match

Most hybrid inverters work with:

- Low voltage (48V or 51.2V) for residential systems (<10 kW)

- High voltage (200–800V) for C&I systems (>30 kW)

✅ Always match the inverter’s DC voltage range with the nominal voltage and configuration (series/parallel) of your battery.

(2) Current Match

Check the max discharge current of the battery: P=V×IP = V × IP=V×I

Example:

A 51.2V 200Ah battery →

Max discharge = 100A → 5.12 kW

If you install two in parallel:

→ 10.24 kW maximum continuous discharge.

So, this battery setup can safely support a 10 kW hybrid inverter.

⚠️ If your inverter’s rated power exceeds the battery’s discharge limit, the inverter may trip during peak loads.

(3) Energy Capacity

Battery energy (kWh) = Voltage × Capacity (Ah) ÷ 1000

Example:

51.2V × 200Ah = 10.24 kWh

If your daily load is 5 kWh, one battery gives ~2 days of backup (without solar input).

✅ Design tip:

Battery energy (kWh) ≥ daily load × autonomy days (1–2 typical)

5. Step 3: Check PV Array Input Limits

A hybrid inverter also has MPPT (Maximum Power Point Tracker) inputs with:

- Maximum PV input power (kWp)

- Voltage range (Vmppt)

- Max current (A)

You should oversize PV power by 1.1–1.3× the inverter’s rated AC power.

Example:

For a 5 kW inverter, PV input = 5.5–6.5 kWp

This ensures full utilization during cloudy conditions.

✅ Design rule: PVinput=1.2×InverterACPV_{input} = 1.2 × Inverter_{AC}PVinput=1.2×InverterAC

Also, ensure:

- Vmppt range of the inverter matches your PV string design.

- Voc (open-circuit voltage) in cold weather stays below inverter’s max DC voltage.

🧮 Proper string design avoids “PV overvoltage” faults and maximizes harvest.

6. Step 4: Balance All Three Elements

A good hybrid design balances load, battery, and PV capacity.

| Component | Typical Ratio | Purpose |

|---|---|---|

| Inverter Power | 1.0× (base) | Defines system power output |

| Battery Energy | 1.5–2.0× inverter rating (kWh) | Provides stable backup time |

| PV Array | 1.2–1.3× inverter rating (kWp) | Maximizes solar generation |

Example:

For a 5 kW inverter:

- PV = 6 kWp

- Battery = 10 kWh

This configuration ensures balanced operation and good economics.

7. Common Mistakes in Hybrid Inverter Sizing

❌ 1. Undersized inverter

- Can’t handle surge loads

- Frequent tripping or overload protection

❌ 2. Oversized inverter

- Wastes money and reduces efficiency at low load

- Idle consumption becomes significant

❌ 3. Battery voltage mismatch

- Using 48V battery on 200–800V inverter or vice versa

❌ 4. PV oversizing beyond limits

- May trigger MPPT shutdown or fault codes

❌ 5. Ignoring communication protocols

- BMS and inverter must use matching RS485/CAN communication

⚠️ Always confirm inverter–battery protocol compatibility before purchase.

8. Example Sizing Scenarios

| System Type | Inverter | Battery Bank | PV Array | Notes |

|---|---|---|---|---|

| Home (Basic) | 3.6 kW | 51.2V 200Ah (10 kWh) | 4.5 kWp | Backup & self-consumption |

| Home (Large) | 5 kW | 51.2V 280Ah (14 kWh) | 6 kWp | Extended backup |

| SME Workshop | 10 kW | 51.2V 560Ah (28 kWh) | 12 kWp | Load shifting, peak shaving |

| C&I System | 50 kW | 512V 200Ah (102 kWh) | 65 kWp | High voltage ESS |

9. Verification Checklist Before Purchase

✅ Verify all datasheets:

- Rated AC power & surge power

- PV input limits (V, A, kWp)

- Battery voltage window and current limits

- Communication protocol (CAN/RS485 compatibility)

- Efficiency (≥96%) and THD (<3%)

✅ Ask supplier for:

- Wiring diagrams

- Tested inverter-battery combinations

- Firmware update support

✅ Conduct on-site or factory acceptance testing if possible.

Sizing a hybrid inverter is not just about matching power numbers — it’s about creating balance between energy sources and consumption.

Key Takeaways:

- Start from actual load demand.

- Match inverter voltage and current with battery specs.

- Keep PV input within safe oversizing range (1.2×).

- Always confirm BMS–inverter compatibility.

A properly sized hybrid inverter ensures longer equipment life, better efficiency, and satisfied end-users — the foundation of any successful PV + storage business.