Practical Strategies to Reduce Peak Demand, Improve Flexibility, and Control Long-Term Costs

Industrial campuses—manufacturing parks, logistics hubs, technology zones, and large commercial estates—face rising energy costs driven by peak demand charges, load variability, and increasing electrification. Traditional centralized storage systems often struggle to adapt to these complex, distributed energy profiles.

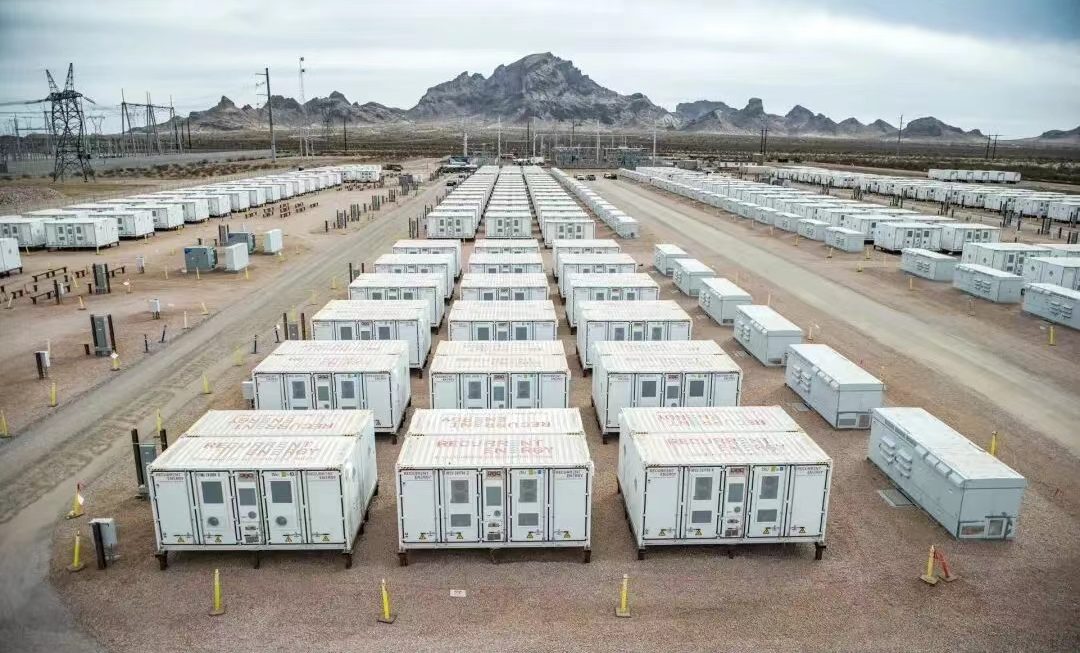

Modular energy storage, when deployed strategically, provides a flexible and scalable way to optimize energy costs without overcommitting capital or operational complexity.

This article explores how modular storage can be used to optimize energy costs in industrial campuses, focusing on deployment strategies, control logic, and real-world decision-making.

1. Why Energy Costs Escalate in Industrial Campuses

Industrial campuses typically experience:

- High and unpredictable peak demand

- Diverse load profiles across buildings or tenants

- Staggered operating schedules

- Limited ability to coordinate all loads centrally

Cost drivers include:

- Demand charges

- Time-of-use tariffs

- Capacity penalties

- Inefficient generator or grid usage

The problem is not total energy use—it’s when and where energy is consumed.

2. Why Modular Storage Outperforms Centralized Systems

Limitations of Centralized Storage

- Single point of failure

- High upfront CAPEX

- Overdesign to cover worst-case scenarios

- Limited flexibility as campus loads evolve

Advantages of Modular Storage

- Incremental deployment

- Load-proximate installation

- Better fault isolation

- Easier expansion and replacement

Modular storage aligns better with the organic growth of industrial campuses.

3. Modular Storage Deployment Models

Building-Level Storage

- Installed near individual factories or facilities

- Targets local peak demand

- Reduces internal distribution stress

Best for:

- Tenants with distinct load profiles

- Energy cost allocation clarity

Zone-Level Storage

- Shared by several buildings

- Managed by campus EMS

Best for:

- Coordinated peak shaving

- Tariff optimization

Hybrid Deployment (Recommended)

- Small storage units at building level

- Larger shared storage at campus level

This approach balances flexibility and cost efficiency.

4. Cost Optimization Mechanisms Enabled by Modular Storage

Peak Demand Shaving

- Discharge storage during short-duration peaks

- Reduce demand charges without oversizing

Time-of-Use Arbitrage

- Charge during off-peak hours

- Discharge during high-tariff periods

Load Smoothing

- Reduce sudden load ramps

- Improve transformer and infrastructure utilization

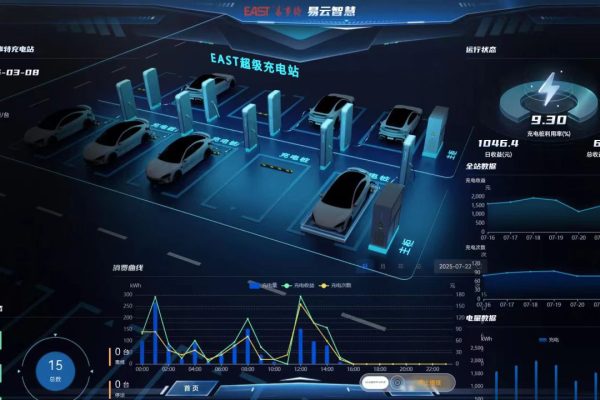

5. Control Strategy: Simple and Hierarchical

A practical control hierarchy:

- Each module optimizes local loads

- Campus EMS coordinates inter-module behavior

- Storage prioritizes cost reduction over energy autonomy

- Grid interaction remains predictable and compliant

Avoid centralized micromanagement of every module—it increases failure risk.

6. Integrating PV and Other Distributed Energy Resources

Modular storage works best when paired with:

- Rooftop or ground-mounted PV

- EV charging infrastructure

- Flexible industrial loads

Key Benefits

- Higher PV self-consumption

- Reduced grid export penalties

- Localized energy balancing

7. Scalability and Future-Proofing

Industrial campuses evolve:

- New tenants arrive

- Processes electrify

- Energy tariffs change

Modular storage allows:

- Phased investment

- Technology upgrades

- Battery chemistry transitions without full system replacement

8. Reliability and Maintenance Considerations

- Isolate failures at module level

- Schedule maintenance without campus-wide disruption

- Standardize spare parts

- Reduce operational risk

Reliability is a financial metric in industrial energy systems.

9. Common Design Mistakes to Avoid

- Oversizing modules to cover all peaks

- Overcomplicating EMS logic

- Ignoring tenant-level incentives

- Treating storage as backup power only

- Delaying deployment waiting for “perfect” conditions

10. EPC and Decision-Maker Checklist

Before implementing modular storage:

- Map load profiles by zone

- Identify peak cost drivers

- Define clear optimization objectives

- Plan for staged deployment

- Align incentives across stakeholders

Modular Storage Turns Energy Costs into a Controllable Variable

Energy cost optimization in industrial campuses is no longer about buying cheaper electricity—it’s about controlling when and where energy flows.

Modular storage provides:

- Financial flexibility

- Operational resilience

- Scalable investment

- Lower long-term energy risk

For EPCs, integrators, and campus operators, modular storage is one of the most practical tools available to manage rising energy costs without locking into rigid infrastructure.