A Practical Framework for Faster, Safer, and More Repeatable ESS Installations

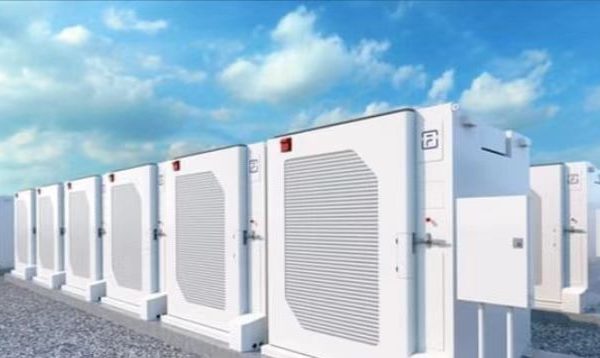

As commercial and industrial customers demand faster deployment, lower engineering cost, and predictable operation from energy storage systems (ESS), modular storage architectures have become the preferred approach for EPC teams.

However—successful modular ESS deployment is not only about choosing the right battery or inverter. It requires a standardized engineering toolkit covering design templates, installation workflows, commissioning checklists, and long-term monitoring practices.

This article presents a ready-to-apply deployment toolkit that EPC teams can use to streamline engineering, reduce failures, and scale to multiple sites efficiently.

1. Why EPC Teams Benefit from a Modular ESS Toolkit

Across many deployments, the most common challenges include:

- Repeated engineering design from scratch

- Installation inconsistencies between different teams

- Communication mismatches between battery–inverter–EMS

- Missing documentation for troubleshooting

- Difficult expansion or multi-site replication

A standardized toolkit solves these issues by ensuring:

- Faster deployment

- Predictable performance

- Lower engineering cost

- Improved reliability

- Easier technician training

The goal is simple:

Design once → Repeat everywhere → Maintain with minimal effort.

2. Core Components of a Modular ESS Deployment Toolkit

Below is the recommended architecture for EPC teams to adopt.

2.1 Standard System Templates (kW/kWh Modules)

EPC teams should maintain pre-engineered configurations such as:

- 30 kW / 60 kWh

- 50 kW / 120 kWh

- 100 kW / 240 kWh

- 200 kW / 500 kWh

Each template includes:

- Battery rack diagrams

- Inverter/PCS wiring

- DC protection set

- EMS integration rules

- Thermal & ventilation design

- Cable routing layout

This reduces engineering time by 50–70% per project.

2.2 Installation Workflow Templates

A standardized installation kit contains:

✔ Mechanical installation sequence

- Battery racks

- Inverter mounting

- Busbar/cabling supports

- Airflow ducts

✔ Electrical installation checklist

- Torque settings

- Cable labeling guidelines

- Grounding rules

- Battery–inverter communication validation

✔ Safety protocols

- LOTO procedures

- DC isolation testing

- Pre-energization check

This ensures cross-team consistency across all sites.

2.3 Commissioning Toolkit

One of the most important parts of modular ESS deployment.

Toolkit should include:

- BMS–EMS communication validation checklist

- Battery SOC calibration flow

- Inverter protection setting presets

- Load bank test protocol

- Thermal validation procedure

- EMS scenario testing (peak shaving, backup mode, PV charging)

Commissioning templates remove guesswork and reduce early-stage failures.

2.4 Monitoring & Reporting Toolkit

A unified monitoring structure helps EPC teams operate multiple small ESS installations.

Toolkit includes:

- Standard KPI dashboard

- Alarm classification (3-level severity)

- Monthly performance report template

- Preventive maintenance scheduling rules

- Remote firmware update SOP

This enables predictable O&M workflows.

3. Engineering Best Practices for Modular ESS

3.1 Use Repeatable Physical Layouts

Every system design should use:

- Standard cabinet dimensions

- Consistent busbar/cable routing

- Fixed battery rack layouts

- Unified grounding points

This reduces installation errors and speeds up technician training.

3.2 Pre-Configured EMS Rulesets

Every modular ESS should ship with:

- Default peak shaving rule

- Default SOC window (20–90%)

- Load priority table

- Backup mode template

- PV self-consumption logic

EPC teams can then fine-tune based on customer demand without rebuilding logic.

3.3 Integrated Thermal Design

Modular ESS reliability is often determined by:

- Airflow patterns

- Battery temperature uniformity

- Inverter cooling path

- Compartment separation

Toolkit items include:

- Ventilation calculation sheet

- Cabinet thermal map template

- Fan/vent placement configuration

This prevents thermal drift and premature battery aging.

3.4 Standardized DC Protection Blocks

All modules should share the same protection structure:

- Battery fuse / DC breaker

- Surge protection

- Emergency stop circuit

- Pre-charge circuit template

This avoids mis-coordination issues that commonly appear in early deployments.

4. A Practical Deployment Example: 100 kW / 240 kWh Modular ESS

Site:

Small manufacturing building with frequent demand spikes and limited grid capacity.

Toolkit used:

- Standard template 100 kW PCS block

- 40 kWh battery module × 6 units

- Pre-built EMS configuration

- Standard commissioning checklist

Deployment Time: Cut in Half

- Traditional design: 8–10 days engineering + 5 days installation

- With toolkit:

- Engineering: 2 days

- Installation: 3 days

- Commissioning: 1 day

Performance Improvement

- 22% peak shaving achieved

- Zero communication faults

- Stable battery temperature within 24–32°C

- Easy documentation handover to client

This demonstrates the power of deploying repeatable ESS structures.

5. Training & Documentation Toolkit for EPC Teams

A scalable deployment system includes:

- Technician training manuals

- Troubleshooting flowcharts

- Quick-start installation guides

- Safety handling instructions

- As-built drawing package templates

This ensures any new team member can follow the same standards.

6. What EPC Teams Can Standardize Next

To further improve scalability:

✔ SKU-Based Storage Modules

Pre-defined 20–40 kWh battery blocks.

✔ Color-coded wiring & labels

Fast fault tracing.

✔ Unified PCS firmware versions

Eliminate incompatibility issues.

✔ Distributor-ready BOM packages

Simplify procurement.

✔ Digital commissioning app

Auto-generates test reports.

Implementing these upgrades transforms an EPC from a “project company” into a repeatable product-driven integrator.

A modular ESS deployment toolkit enables EPC teams to scale efficiently by transforming energy storage from custom-engineered projects into repeatable productized solutions.

By standardizing system templates, installation workflows, commissioning procedures, and monitoring packages, EPC teams can deliver:

- Faster project delivery

- Higher reliability

- Lower engineering workload

- Consistent performance across sites

This approach is key for EPCs that aim to grow into multi-site, multi-country operators in the next phase of commercial and industrial energy storage development.