Industrial parks and commercial facilities are increasingly adopting energy storage systems to manage rising electricity costs and ensure greater energy efficiency. One of the key benefits of energy storage in such settings is peak shaving — a method of reducing energy demand during peak periods to avoid high electricity rates and improve overall energy management.

In this article, we will explore modular energy storage systems, their role in peak shaving for industrial parks, and why they are an ideal solution for businesses seeking to reduce energy costs and improve sustainability.

1. What is Peak Shaving?

Peak shaving refers to the practice of reducing energy consumption during peak demand periods, when electricity rates are highest. Industrial parks typically experience substantial energy usage spikes due to the operational hours of factories, machinery, HVAC systems, and lighting.

During these peak hours, electricity rates are often several times higher than during off-peak periods. By strategically managing energy use, businesses can avoid peak demand charges and reduce their electricity bills.

2. Why Energy Storage is Essential for Peak Shaving

Energy storage systems, particularly battery energy storage systems (BESS), allow industrial parks to store energy during off-peak hours (when electricity is cheaper) and use that stored energy during high-demand periods. This strategy provides several key benefits:

- Cost Savings: Storing energy during off-peak times and using it during peak times can significantly reduce demand charges and energy costs.

- Grid Independence: Energy storage can provide backup power during grid outages, ensuring that operations continue even during electrical disturbances.

- Energy Efficiency: Storage systems can help smooth out fluctuations in energy supply and demand, improving the overall efficiency of the energy system.

- Sustainability: By using stored renewable energy (such as solar or wind), industrial parks can reduce reliance on fossil fuels and lower their carbon footprint.

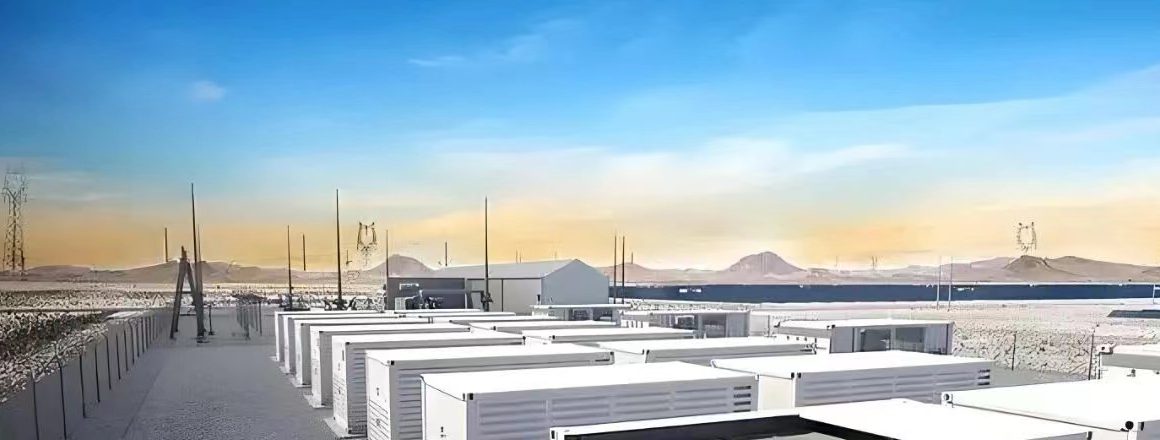

3. Modular Energy Storage: What Makes It Ideal for Industrial Parks?

Unlike traditional, single-unit energy storage systems, modular energy storage systems consist of multiple, smaller battery modules that can be easily scaled to meet specific energy needs. These modular systems offer several advantages over non-modular or centralized systems.

Key Benefits of Modular Energy Storage for Industrial Parks:

- Scalability: Modular systems can be expanded or downsized depending on the energy requirements of the industrial park. As energy demand grows or decreases, additional battery modules can be added or removed without a major overhaul. This flexibility allows for a tailored solution that can evolve with the business.

- Efficiency: Modular systems tend to be more efficient than traditional large-scale installations because they provide more localized energy storage, reducing transmission losses.

- Redundancy: In case of a failure in one module, the system continues to operate using the remaining modules, ensuring uninterrupted energy supply and reducing the risk of downtime.

- Cost-Effective Implementation: Rather than investing in a large, upfront energy storage system, businesses can start with a smaller, modular installation and gradually increase capacity as needed. This approach makes modular systems an attractive option for businesses with budget constraints or uncertain future needs.

- Flexibility for Integration: Modular systems can integrate easily with existing renewable energy sources, such as solar, wind, or cogeneration systems, to further enhance energy efficiency and reduce reliance on the grid.

4. How Modular Energy Storage Works for Peak Shaving

To understand the application of modular energy storage in peak shaving, it’s important to look at how the system operates in a real-world industrial park setting.

1. Energy Storage During Off-Peak Hours

At night or during periods of low energy demand, energy storage systems can charge using electricity from the grid or renewable energy sources, such as solar PV or wind turbines. During these times, energy rates are at their lowest, allowing the system to fill the batteries with inexpensive power.

2. Discharge During Peak Hours

During peak periods — typically during the day when factory operations are in full swing — the system discharges the stored energy to meet the demand. This helps to avoid pulling excessive power from the grid, which is typically more expensive during these peak times.

For example, if the industrial park’s average energy demand during the day is 500 kW, but the grid supply would cost more due to high demand charges, the energy storage system can provide 200 kW from its batteries, helping to reduce the total demand that needs to be met from the grid.

3. Dynamic Charging and Discharging Control

A key feature of modular energy storage systems is the dynamic management of energy flow. The system uses smart inverters and energy management software to control when and how energy is stored and discharged, based on real-time data about energy usage, pricing, and grid conditions.

5. Key Considerations for Implementing Modular Storage in Industrial Parks

When considering modular energy storage for peak shaving, industrial park managers must consider several factors to ensure optimal system performance.

a. Energy Demand Profiling

Before installation, an energy audit should be performed to understand the load profile of the industrial park. This involves identifying periods of high energy consumption and potential savings from peak shaving. By understanding the precise demand curve, the modular storage system can be sized and configured to maximize cost savings.

b. System Sizing

The size of the battery storage system should be based on:

- Peak demand reduction goals

- Available renewable generation (if any)

- Energy consumption patterns

The modular nature allows businesses to start with a smaller system and scale up as needs grow, but the initial sizing must be done carefully to ensure effective peak shaving.

c. Integration with Renewable Energy

For industrial parks that already have solar or wind installations, modular energy storage systems provide a seamless way to store excess energy generated during off-peak hours and discharge it when the renewable output is insufficient (e.g., at night or during cloudy periods). This reduces the reliance on grid-supplied electricity and increases sustainability.

d. Maintenance and Monitoring

Routine maintenance and continuous remote monitoring of the modular energy storage system are essential to ensure long-term performance. Most modular systems come with advanced monitoring tools that provide real-time data on energy storage levels, system health, and performance metrics.

e. Regulatory and Incentive Considerations

In many regions, businesses can take advantage of government incentives or tax rebates for investing in energy storage systems, especially when coupled with renewable energy generation. It’s essential to stay informed about local regulations and policies to maximize financial incentives.

6. Case Study: Modular Energy Storage for Peak Shaving in an Industrial Park

Consider the case of an industrial park with 10 factories that collectively consume 4 MW of electricity during peak hours. Without energy storage, the facility’s utility bill is significantly higher due to peak demand charges.

Solution:

A modular battery storage system is installed with an initial capacity of 1 MW. During peak periods, the system discharges 500 kW of stored energy, reducing the need for the factories to pull the full 4 MW from the grid. The remaining 3.5 MW is met through grid supply, but the demand charge is now reduced because the park only draws 3 MW from the grid instead of 4 MW.

Results:

- Reduced peak demand: The peak demand charge drops by 25%.

- Cost savings: The industrial park saves a significant amount on electricity bills annually.

- Scalability: As energy consumption increases, additional modular units are added, expanding the system’s capacity to meet growing needs without significant infrastructure changes.

7. The Future of Modular Storage in Industrial Parks

As industrial parks and commercial facilities continue to prioritize energy efficiency and cost savings, modular energy storage systems are emerging as a flexible, scalable, and cost-effective solution. Peak shaving, made possible by these systems, allows businesses to control energy costs, reduce grid dependence, and improve sustainability.

By providing the flexibility to expand as needed, modular storage systems ensure that industrial parks can adapt to changing energy demands and take full advantage of renewable energy resources.

For businesses looking to optimize their energy usage and reduce electricity bills, modular storage for peak shaving is not just a short-term solution but a long-term investment in a smarter, more efficient future.