How to Optimize Systems Year-Round for Reliability and ROI

1. Why Seasonal Performance Matters

A PV + storage system isn’t static. Its performance varies with seasonal sunlight, temperature swings, and energy demand patterns. For project developers, installers, and C&I buyers, overlooking these fluctuations can lead to underperformance, shorter battery lifespan, and unhappy customers.

By understanding seasonal effects and preparing your system accordingly, you can:

- Maximize energy yield across all months.

- Avoid system stress during peak heat or cold.

- Ensure stable ROI for small commercial and residential projects.

2. Seasonal Challenges in PV + Storage

Summer

- High irradiance increases energy production.

- High ambient temperatures reduce inverter and battery efficiency.

- Air conditioning demand spikes load requirements.

Winter

- Shorter days and low irradiance reduce solar generation.

- Cold weather reduces battery capacity temporarily (especially lithium-ion).

- Heating demand shifts load profiles.

Spring & Autumn

- Transition months bring variable weather.

- Storm risks (rain, wind, snow melt) can test system resilience.

3. Seasonal Tips for PV Modules

- Angle Adjustment: In regions with strong seasonal changes, adjusting the tilt angle of PV modules twice a year improves yield.

- Snow and Dust Removal: Snow cover in winter and dust in dry seasons block light. Cleaning schedules should be seasonal.

- Shading Analysis: Trees and buildings cast different shadows in summer vs. winter due to sun angle. Recheck shading seasonally.

4. Seasonal Tips for Inverters

- Temperature Management:

- Summer: Ensure proper ventilation, shading, or even active cooling for outdoor inverters.

- Winter: Protect against condensation and freezing in humid/cold climates.

- Firmware Updates: Many inverter manufacturers release seasonal performance firmware (efficiency tweaks, grid-support features). Plan updates during low-demand seasons.

- Load Shifting Settings: Adjust time-of-use settings for changing demand (e.g., longer evening heating loads in winter).

5. Seasonal Tips for Battery Storage

- Temperature Control:

- Lithium-ion batteries perform best between 15–30°C.

- In summer, avoid overheating (>40°C) with HVAC or passive cooling.

- In winter, pre-heating or insulated enclosures maintain performance.

- Capacity Planning:

- Expect 10–20% capacity loss in cold climates. Oversize winter-critical systems accordingly.

- For off-grid sites, design autonomy for worst-case winter sunlight.

- Cycle Strategy:

- In summer: Use batteries for peak-shaving during cooling loads.

- In winter: Prioritize self-consumption storage when PV production is low.

6. Seasonal Grid Interaction

- Summer peak loads: Sell surplus PV power back to the grid during midday when demand is high.

- Winter evening peaks: Batteries can cover more expensive grid tariffs at night.

- Storm season: Enable islanding and backup functions in advance, ensuring the system seamlessly transitions during outages.

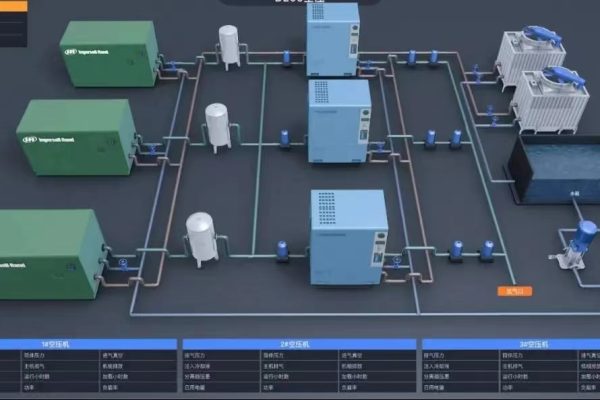

7. Monitoring & EMS Adjustments

A modern Energy Management System (EMS) can automate seasonal optimization:

- Adjust charge/discharge windows based on utility rates.

- Monitor real-time weather data to predict PV generation.

- Integrate seasonal demand forecasts for smarter dispatch.

Tip: Review EMS settings at least quarterly — many system owners never revisit after commissioning, leaving efficiency on the table.

8. Case Example – Small Commercial Project

A 100 kW PV + 200 kWh battery system at a food processing facility in a temperate region:

- Summer:

- PV oversupply covers refrigeration loads.

- EMS shifts midday generation into peak evening usage.

- Winter:

- PV generation drops by 40%.

- Battery reserved mainly for peak tariff support at night.

- Result: The system maintains 20–25% annual savings even with large seasonal differences.

9. O&M Scheduling by Season

- Spring: Panel inspection after winter storms; battery health check.

- Summer: HVAC and cooling check for inverters/batteries.

- Autumn: Leaf and debris removal; prep for snow loads.

- Winter: Emergency backup test; insulation and heating system check.

Regular seasonal maintenance ensures reliability and prevents costly downtime.

10.Seasonal Planning = Long-Term Value

PV + storage performance is never the same in July as it is in December. Integrators and customers who plan for seasonal changes will enjoy:

- Higher year-round efficiency.

- Extended component lifespan.

- Better financial performance with fewer surprises.

Seasonal optimization transforms PV + storage from a static installation into a dynamic energy asset that adapts to real-world conditions.