What to Avoid to Protect Your Budget, Safety, and System Performance

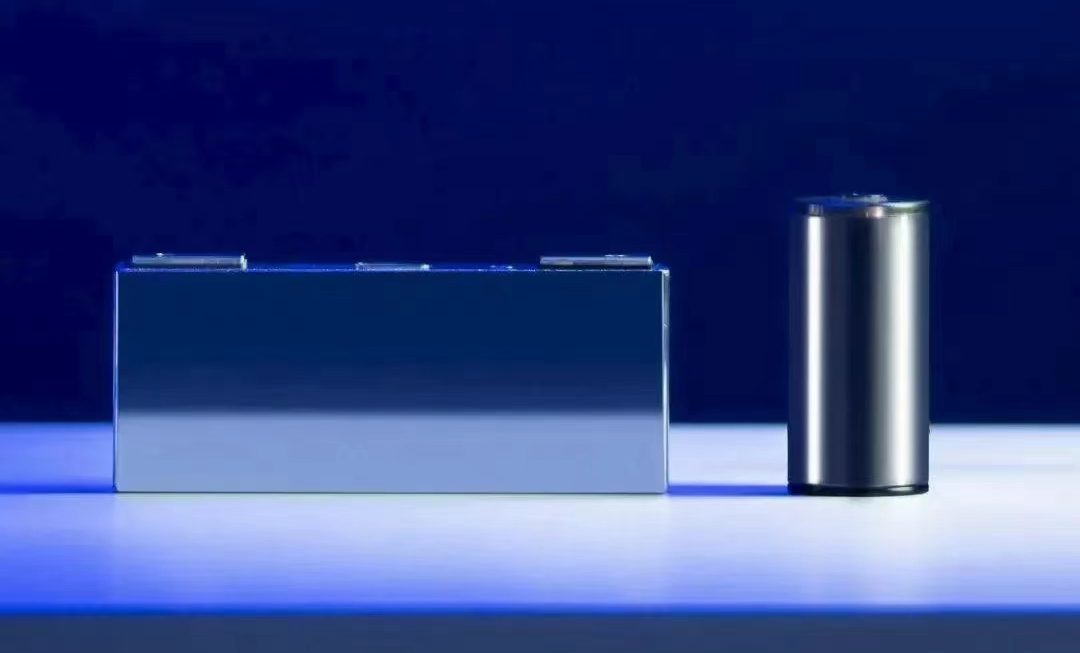

In the growing market for residential energy storage, batteries are no longer just an optional add-on to solar systems — they are becoming a key part of backup power, peak shaving, and energy independence.

But for many system buyers, especially small EPCs, installers, and resellers, battery sourcing can be tricky. With hundreds of SKUs available and technical details that seem similar at a glance, making the right purchase isn’t just about finding the lowest price.

In this article, we highlight the top five mistakes that commonly lead to system failure, underperformance, or added cost — and how to avoid them.

1. Focusing Only on Price per kWh

A low price per kWh can be tempting. But if it comes with trade-offs in:

- Shorter cycle life

- Poor thermal stability

- Incompatible BMS

- Lack of certifications

…the long-term cost may be much higher.

📌 Example:

A 10kWh battery priced at $280/kWh may seem better than a $320/kWh alternative. But if the cheaper unit has a cycle life of only 2,000 vs. 6,000, your dollar-per-cycle cost triples.

💡 Better approach:

Calculate total energy throughput per dollar (Wh × cycles ÷ price). And always factor in warranty terms, replacement logistics, and BMS compatibility with your inverter.

2. Ignoring Battery and Inverter Voltage Matching

One of the most common and costly mistakes in small-scale projects is selecting a battery whose nominal voltage does not match the inverter’s required input range.

Common mismatches include:

- Buying a 48V battery for an inverter that needs 80–120V

- Sourcing a high-voltage stack for a hybrid inverter only compatible with low-voltage packs

- Forgetting to verify startup voltage thresholds under load

This leads to startup failures, reduced usable energy, or outright inverter damage.

💡 Solution:

Check inverter datasheets for:

- Battery voltage window (min/max)

- Charge/discharge current limits

- Supported BMS communication protocols (CAN, RS485)

Then confirm your battery spec aligns on all three.

3. Underestimating Communication Protocol Complexity

Many home battery buyers assume that “as long as it’s 48V, it will work.”

But for modern hybrid inverters, battery communication matters as much as voltage.

Without proper BMS-to-inverter communication:

- You lose accurate SoC readings

- The inverter may miscalculate charge/discharge timing

- You risk overcharging or deep discharge — reducing battery life

Some battery brands offer “universal” BMS interfaces, but real-world plug-and-play is rare unless the manufacturer has validated the pairing.

💡 Pro tip:

Request a compatible inverter list from the battery vendor. Or work with a supplier who offers pre-configured pairings with software-level validation and support.

4. Forgetting About Installation and Local Compliance

You might source a great battery — but still run into problems if:

- The cabinet is too tall/wide for the utility room

- The connectors don’t match your existing inverter wiring

- The battery lacks UL, IEC, or local grid compliance documents

- Shipping documents are incomplete (especially for dangerous goods)

For residential projects, space, safety, and paperwork matter just as much as chemistry.

💡 Avoid surprises by checking:

- Dimensions and weight (wall-mount vs. floor-stack vs. rack)

- Installation manuals with clearance and ventilation guidelines

- Local fire code requirements (especially for indoor storage)

- Availability of test reports and DoC/CE/UL markings

5. Overlooking Future Flexibility and Serviceability

Not all buyers consider what happens in 2–3 years when:

- The homeowner adds an EV

- They want to add 5kWh more capacity

- A battery cell fails and needs replacement

Many low-cost systems are closed, meaning:

- No easy expansion port

- Firmware not upgradable

- Spare parts unavailable

- No remote monitoring tools

This locks the installer and end user into a hard-to-maintain system.

💡 Ask your supplier:

- Is this system modular or expandable?

- Can you provide firmware updates remotely?

- Is there a local repair center or RMA policy?

Look for brands that treat you as a long-term partner — not just a buyer of one shipment.

Bonus: Battery + Inverter = One Sourcing Decision

In real-world residential projects, battery and inverter should be treated as one system, not two separate purchases.

A mismatched system may:

- Cause delays at commissioning

- Fail at peak loads

- Void warranties on both sides

That’s why many installers prefer to work with technical sourcing partners who can:

- Match inverter and battery specs

- Pre-test communication

- Offer full documentation and installation support

- Help with sizing, cables, and accessories

This reduces friction for first-time users and increases long-term satisfaction.

Summary: What to Ask Before You Buy

| Question | Why It Matters |

|---|---|

| What is the real cycle life under 0.5C/1C? | Determines cost per usable kWh |

| Is the BMS tested with my inverter? | Prevents integration errors |

| Does the voltage range align with inverter input? | Ensures startup and performance |

| Are documents available for local grid/fire compliance? | Avoids delays and penalties |

| Is the system modular, upgradeable, and serviceable? | Future-proofs your installation |

By avoiding these top five mistakes, you protect not only your system — but also your time, reputation, and customer relationships.

Choose battery partners who understand the full project, not just the chemistry.