In the fast-growing energy storage and solar industry, buyers often hope to find a single supplier who can deliver everything — from solar panels, inverters, and batteries to cables, racks, and complete system integration.

At first glance, the “one supplier for everything” concept sounds efficient and convenient.

However, in real-world PV + ESS (Energy Storage System) projects, this expectation rarely works as planned.

Different components require specialized expertise, certifications, and production standards that no single company can fully master.

This article explains why relying on one supplier for everything is a myth, how to build a strategic multi-supplier approach, and what to look for in a true system integration partner.

1. The Appeal of the “One Supplier” Promise

Buyers — especially new distributors or EPCs — often seek a single point of contact to save time and reduce risk.

Common reasons include:

- Simplified purchasing process

- One quotation and unified logistics

- Easier warranty and communication

- Belief that “complete packages” ensure compatibility

📦 At the quotation stage, a “one-stop solution” sounds perfect — but the reality behind it can be far more complex.

2. The Reality: Specialization Rules the Energy Storage Industry

Each component of a hybrid energy system has its own technical ecosystem and certification process.

| Product | Specialization Required | Typical Expertise |

|---|---|---|

| PV Panels | Cell efficiency, PID resistance, temperature coefficient | Solar cell R&D, module manufacturing |

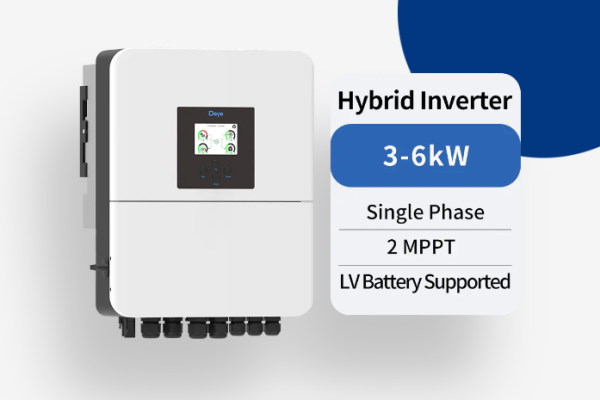

| Inverters | MPPT algorithms, EMC testing, firmware control | Power electronics design |

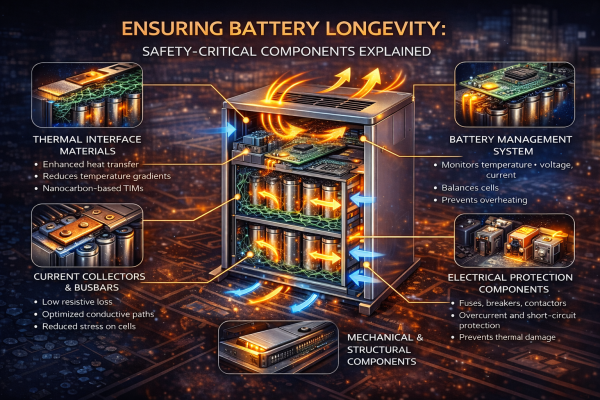

| Batteries | BMS software, cell balancing, safety testing | Electrochemistry, pack design |

| BOS Components | Surge protection, cabling, breakers | Electrical hardware and safety standards |

🧠 No single company can maintain deep expertise, certifications, and factory lines across all four domains at industrial scale.

3. Why “All-in-One” Factories Often Outsource Components

Many so-called “one-stop” suppliers actually buy and rebrand components from specialized partners.

For example:

- A “solar + storage” brand may source inverters from an OEM factory.

- A “battery system” supplier might use third-party PV modules.

- “Complete solutions” often combine products from multiple factories under one label.

While this approach is not necessarily bad, it means the core technology still comes from specialized sources, and integration quality depends on the supplier’s engineering capacity.

⚙️ A true solution provider integrates — not manufactures — every component.

4. The Risk of Over-Reliance on One Supplier

(1) Quality Inconsistency

If your “one supplier” changes OEM partners without notice, your next shipment may differ in performance or design.

(2) Limited Technical Support

A single supplier may not have engineers familiar with every subcomponent (e.g., inverter firmware or BMS protocol).

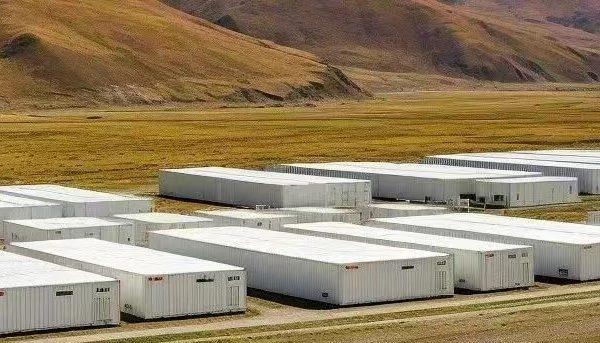

(3) Supply Chain Vulnerability

If that factory faces raw material delays or policy restrictions, your entire project timeline can collapse.

(4) Higher Long-Term Costs

Without price benchmarking between multiple sources, you may overpay for bundled packages.

🚧 Dependence on one vendor is convenient today but risky tomorrow.

5. Why Multi-Supplier Collaboration Works Better

A well-structured multi-supplier model combines specialized expertise and customized value.

| Category | Select From | Benefit |

|---|---|---|

| Batteries | Tier-1 pack manufacturers | Quality, warranty, safety |

| Inverters | Certified hybrid inverter makers | Grid compliance, firmware updates |

| PV Modules | Bankable solar brands | Efficiency and reliability |

| Cables/BOS | Regional suppliers | Lower logistics cost |

🔋 Each supplier focuses on its strength — you assemble the best combination for your market.

6. The Role of a System Integrator

A system integrator bridges the gap between multi-supplier sourcing and turnkey solutions.

(1) Compatibility Engineering

- Ensures communication between BMS and inverter via RS485/CAN protocols.

- Matches voltage windows, charge current, and PV input ranges.

(2) Testing and Validation

- Performs pre-delivery testing of hybrid setups in controlled conditions.

- Verifies compliance with UL/IEC standards.

(3) Documentation and Support

- Provides one unified system manual and schematic wiring diagrams.

- Offers after-sales support even if components come from multiple factories.

🧩 A skilled integrator gives you “one solution” — not necessarily “one manufacturer.”

7. Building an Efficient Multi-Supplier Strategy

(1) Start with a Core Component

Choose one product as your foundation — typically the inverter or battery — and match all other parts to it.

(2) Establish a Qualification List

Vet each supplier based on:

- Factory scale and quality certifications (ISO, IEC, UL)

- Export experience and documentation

- Warranty and service capabilities

(3) Standardize Interfaces

Adopt consistent 48V, 100Ah or 51.2V, 280Ah formats, and ensure common communication protocols.

(4) Test in Small Batches

Pilot a small system to verify compatibility and communication before large orders.

(5) Maintain Documentation

Keep a component logbook with datasheets, wiring diagrams, and firmware versions.

📘 A professional sourcing strategy balances diversity and control.

8. Myths and Misconceptions

| Myth | Reality |

|---|---|

| “One supplier ensures perfect matching.” | Integration issues still occur if protocols are not aligned. |

| “It’s cheaper to buy everything from one factory.” | Bundled pricing often hides markups. |

| “Mixing brands creates risk.” | Only if there is no testing or integration. |

| “All-in-one products mean better quality.” | Not always; many are reassembled OEM systems. |

💡 Smart buyers verify, not assume.

9. How to Identify a Reliable Integration Partner

Look for suppliers who:

- Provide detailed wiring and communication diagrams.

- Offer pre-assembled or tested hybrid kits.

- Use branded inverters and battery modules with traceable serial numbers.

- Have engineering teams capable of remote technical support.

🧰 Transparency and technical depth are the signs of a real integration partner, not just a reseller.

10. Real-World Example

A distributor in Southeast Asia tried to purchase a “complete solar + battery system” from one vendor.

Upon installation, the battery could not communicate with the inverter’s BMS, leading to system shutdowns.

The supplier blamed the inverter manufacturer; the inverter maker blamed the battery pack.

After switching to a multi-supplier model — sourcing a certified inverter, verified BMS-compatible battery, and local BOS components — the distributor achieved 98% system uptime and faster technical response.

⚙️ The lesson: Integration matters more than consolidation.

The idea of “one supplier for everything” is more marketing myth than manufacturing reality.

In the energy storage industry, success depends on specialization, verification, and intelligent integration.

✅ Key Takeaways:

- No single supplier can master all components equally.

- Multi-supplier sourcing allows flexibility, control, and better pricing.

- Choose an integration partner, not just a “one-stop” reseller.

- Focus on compatibility testing and documentation.

In the end, what matters is not who made every part — but how well those parts work together in your customer’s system.