How PV-Ready Design Enhances Flexibility, Cost Efficiency, and Market Competitiveness

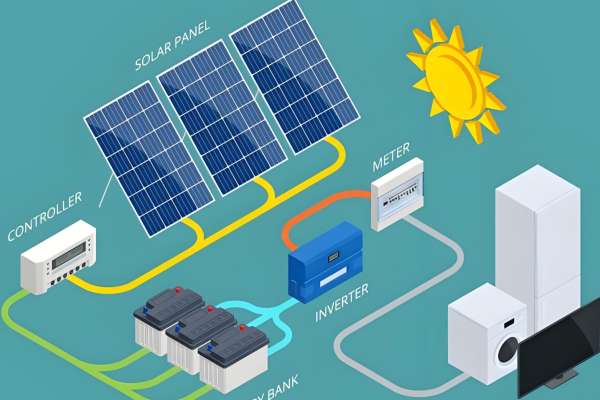

In recent years, the boundaries between solar power (PV) and battery energy storage systems (BESS) have become increasingly blurred.

Buyers today often encounter the term “PV Ready” when evaluating energy storage products. But what exactly does it mean? And why does it matter for installers, EPCs, and project developers?

In the evolving renewable energy landscape, a “PV Ready” battery system represents compatibility, future scalability, and intelligent integration — key factors that influence project ROI and buyer confidence.

This article explains what “PV Ready” means, how it works technically, and why it’s becoming an essential specification in the energy storage industry.

1. What “PV Ready” Really Means

“PV Ready” refers to a battery energy storage system (BESS) that is pre-designed to integrate directly with photovoltaic (solar) systems — either immediately or at a later stage.

✅ In Simple Terms:

A PV Ready battery can connect to a solar inverter or hybrid inverter without major modification.

🔋 In Technical Terms:

It means the system has the electrical interfaces, voltage compatibility, and control logic to handle bi-directional DC or AC coupling with a PV system.

For example:

- The DC voltage range of the battery matches that of a PV inverter.

- The communication protocol (e.g., Modbus, CAN, RS485) is compatible.

- The EMS/BMS software can interpret PV generation signals for charging control.

2. Why “PV Ready” Matters for Buyers

When international buyers evaluate battery systems, they often plan for phased project development — starting with storage or PV, and adding the other later.

Having a PV Ready battery gives them flexibility and future-proof investment.

💡 Key Buyer Benefits:

| Benefit | Explanation |

|---|---|

| 1. Easy PV Integration | No need to replace or reconfigure the storage system when adding solar panels. |

| 2. Lower Installation Cost | Fewer components and wiring changes during later PV connection. |

| 3. Simplified EMS Control | Unified control logic for solar and storage optimization. |

| 4. Future Upgrade Capability | Buyers can scale up their PV system as load demand grows. |

| 5. Faster Project ROI | Combined PV + ESS operation improves self-consumption and grid independence. |

In export markets such as Africa, Southeast Asia, and South America, many clients start with battery backup systems and later add PV arrays when budgets allow.

PV Ready design directly addresses this growing demand.

3. Technical Elements of a PV Ready Battery System

A true PV Ready system must meet both electrical and software readiness criteria.

⚙️ Electrical Readiness

| Component | Design Feature | Description |

|---|---|---|

| DC Bus Interface | Compatible voltage range | Matches PV inverter DC link (e.g., 200–800V). |

| Connectors | MC4 / Anderson types | Allow easy future PV connection. |

| Protection Devices | SPD, DC fuses, isolators | Designed for bidirectional DC flow. |

| Grounding Scheme | Common reference point | Supports combined PV + BESS safety compliance. |

💻 Software & Communication Readiness

| Feature | Purpose |

|---|---|

| EMS protocol (Modbus, CAN) | Communication with PV inverter |

| SOC/SOH synchronization | Unified power control |

| MPPT coordination | Prevents conflicting charge/discharge commands |

| Remote monitoring interface | View both PV and storage data together |

A PV Ready battery cabinet may already include pre-wired terminals, communication ports, and firmware parameters that make integration seamless.

4. PV Ready in Different System Architectures

There are multiple ways to combine PV and energy storage. A PV Ready design can fit any of these common configurations:

4.1. AC-Coupled System

PV inverter and battery inverter are connected to the same AC bus.

- PV Ready means the battery inverter can detect PV output via grid sensors or EMS.

- Example: Retrofitting storage into an existing solar installation.

4.2. DC-Coupled System

PV array and battery share a DC bus connected to a hybrid inverter.

- PV Ready means the battery’s DC voltage, BMS, and control logic match hybrid inverter specifications.

- Example: New residential or C&I hybrid systems.

4.3. Hybrid Inverter Integration

Some hybrid inverters are designed “PV + Battery Ready” by default.

- The battery system’s PV Ready label confirms direct plug-and-play compatibility.

5. PV Ready vs. Non-PV Ready: What’s the Difference?

| Feature | PV Ready System | Non-PV Ready System |

|---|---|---|

| DC Voltage Range | Matches PV inverter (200–800V) | Fixed low-voltage (e.g., 48V) |

| Communication | Supports PV protocols | Limited to standalone BMS |

| EMS Integration | Unified solar-storage control | Separate systems |

| Upgrade Flexibility | Easy PV addition | Requires redesign or replacement |

| Typical Application | C&I, hybrid, microgrid | Backup-only systems |

This comparison clearly shows why PV Ready systems are preferred for future-oriented buyers.

6. Benefits for Distributors and EPC Contractors

From a commercial standpoint, PV Ready systems simplify both sales and installation.

🌍 For Distributors

- Easier to stock one flexible model for multiple project types

- Attracts clients planning phased solar + storage projects

- Reduces after-sales technical complexity

🏗️ For EPC / Installers

- Shorter installation and commissioning time

- Simplified wiring and programming

- Lower risk of mismatch or communication failure

Having “PV Ready” on the product spec sheet also adds marketing value — it signals technological readiness and compatibility.

7. PV Ready in Residential vs. Commercial Applications

| Application | PV Ready Function | Key Advantage |

|---|---|---|

| Residential | Plug-and-play with hybrid inverter | Simplifies rooftop system expansion |

| C&I | EMS-level solar-storage coordination | Enables demand peak shaving and load shifting |

| Telecom / Remote Sites | Integration with solar charger | Improves off-grid reliability |

| Microgrid | Hybrid management of solar + diesel + battery | Provides full energy autonomy |

In C&I or microgrid applications, PV Ready systems can even balance multiple generation sources, improving energy flow stability and cost efficiency.

8. Common Misunderstandings About “PV Ready”

❌ Myth 1: “PV Ready means it already has solar panels.”

Truth: It means the system is ready to connect with PV, not that PV modules are included.

❌ Myth 2: “All batteries can work with PV systems.”

Not true. Only systems with compatible voltage and control logic are truly PV Ready.

❌ Myth 3: “It’s only a marketing term.”

In reality, it’s a technical specification defined by hardware and communication compatibility.

9. How to Identify PV Ready Products

Buyers should check the technical datasheet and confirm:

- “PV Compatible” or “PV Ready” marked in the specification

- DC voltage range matches the PV inverter

- Supported communication protocols (Modbus, CAN, etc.)

- Integration examples in product manual

Pro Tip:

Ask suppliers for a PV + ESS wiring diagram or successful integration case study — this proves real compatibility, not just marketing claims.

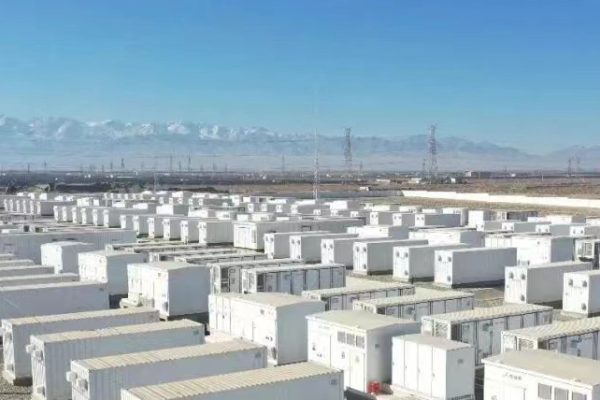

10. PV Ready as a Future Trend

As global demand for solar + storage hybrid systems grows, the PV Ready label will become a standard expectation.

Market Drivers:

- Residential customers adding PV to existing backup systems

- C&I users upgrading from UPS to hybrid storage

- Utility microgrids integrating renewable generation

- Governments promoting self-consumption incentives

Manufacturers who design PV Ready energy storage products will gain a significant competitive edge in international markets.

11. Example: PV Ready Cabinet in Action

Project: 100 kWh LFP Battery Cabinet, Nigeria

Challenge:

Client initially installed battery-only backup for unstable grid. Planned to add PV modules later.

Solution:

Supplied PV Ready cabinet with 300–750V DC range and hybrid inverter interface.

Result:

- One year later, added 50 kWp solar array without system redesign.

- EMS automatically optimized PV charging schedule.

- Payback period reduced by 18%.

This illustrates the real-world value of PV Ready design — flexibility and future savings.

12. Marketing and Communication Tips

If your company produces or supplies PV Ready systems, highlight it clearly in product documentation and marketing:

- Add a “PV Ready” logo on brochures and spec sheets.

- Create an infographic showing easy PV integration steps.

- Share LinkedIn posts demonstrating “PV + ESS upgrade cases.”

- Educate buyers about the technical difference between PV Ready and standard systems.

Educating customers increases perceived value and positions your brand as technically reliable and forward-thinking.

13. Challenges in Implementing PV Ready Design

| Challenge | Solution |

|---|---|

| Communication mismatch between PV inverter and BMS | Develop universal Modbus/CAN profiles |

| Voltage compatibility issues | Offer configurable DC bus voltage |

| Certification (CE, UL, IEC) for PV+ESS | Test as hybrid system from the start |

| Firmware integration | Use modular EMS logic with PV interface |

Overcoming these challenges ensures true interoperability — the foundation of the “PV Ready” promise.

The term “PV Ready” is more than a marketing label — it represents a strategic design philosophy for the next generation of energy storage systems.

A PV Ready battery system provides:

- Seamless solar integration

- Future scalability

- Simplified installation

- Higher ROI for both buyers and integrators

In a world moving toward renewable hybridization, PV Ready systems are not optional — they are the new standard for competitive and intelligent energy storage solutions.

For global suppliers, promoting PV Ready design is an opportunity to stand out — as the market shifts from “backup power” to smart solar storage ecosystems.