Understanding Modern Inverter Technology for Efficient PV + Storage Systems

In the rapidly evolving world of solar and energy storage, inverter technology plays a central role. It determines not only how efficiently DC power from solar panels or batteries converts to AC power, but also how safely and reliably the system operates.

One of the most important advances in recent years is the transformerless inverter — a design that replaces bulky, heavy transformers with advanced power electronics.

But what exactly does “transformerless” mean, and why does it matter for modern PV and battery systems?

Let’s break it down in technical and practical terms.

1. The Role of an Inverter in PV and Storage Systems

Inverters act as the heart of every PV or hybrid storage system. They convert DC electricity from solar panels or batteries into AC power used by appliances, factories, or the grid.

Core Functions:

- DC to AC conversion

- Synchronization with the grid (frequency, voltage)

- Maximum Power Point Tracking (MPPT) for PV efficiency

- Battery management (charging and discharging control)

- System protection and monitoring

Traditionally, inverters included isolation transformers between the DC and AC sides to provide electrical separation and safety. However, new designs have eliminated these heavy components — with remarkable benefits.

2. Transformer vs. Transformerless: The Key Difference

Traditional Transformer-Based Inverter

- Uses a galvanic isolation transformer between DC and AC sides.

- Provides electrical separation to prevent DC current from leaking into the grid.

- Offers high safety but at the cost of size, weight, and efficiency.

Transformerless Inverter

- Uses electronic circuits (IGBTs, MOSFETs, or SiC transistors) instead of a physical transformer.

- Provides software and hardware-based isolation through control logic and filters.

- Delivers higher efficiency, lighter weight, and lower cost.

In short:

A transformerless inverter achieves the same functional result — safe DC-to-AC conversion — without a physical transformer.

3. Why Transformerless Inverters Became Popular

Over the past decade, transformerless design has become standard in most string inverters, hybrid inverters, and residential/commercial storage systems.

The Driving Forces:

| Factor | Transformer Inverter | Transformerless Inverter |

|---|---|---|

| Efficiency | 92–95% | 97–99% |

| Weight | Heavy (40–60kg) | Light (15–25kg) |

| Cost | Higher | Lower |

| Cooling demand | Higher | Lower |

| EMI performance | Simpler | Needs careful grounding |

| Noise level | Moderate | Quieter |

Transformerless designs use high-frequency switching and advanced EMI filters to maintain grid compliance and safety — without the losses and bulk of iron-core transformers.

4. How Transformerless Inverters Work

A transformerless inverter operates using high-efficiency semiconductor circuits to emulate the functions of isolation and current control.

Core Components:

- DC/DC stage — Adjusts PV or battery voltage to inverter input range.

- DC/AC stage — Converts DC to sinusoidal AC using pulse-width modulation (PWM).

- EMI filters — Block DC leakage and reduce noise.

- Ground fault detection — Monitors insulation resistance.

Isolation and Safety Mechanisms:

Even without a physical transformer, these inverters maintain safety through:

- Galvanic isolation at control and signal levels.

- Residual current monitoring (RCM).

- Advanced insulation materials on PCB and enclosure.

- Active leakage current suppression circuits.

This combination ensures compliance with international standards like IEC 62109, VDE 0126-1-1, and UL 1741.

5. Benefits of Transformerless Inverters

1. Higher Efficiency

Eliminating the transformer reduces conversion losses by 2–4%.

That means more solar energy goes directly to the grid or load.

For a 100kW system, a 2% gain equals 2,000 kWh per year — enough to power a small office for months.

2. Reduced Weight and Size

Transformerless inverters are 30–50% lighter, making shipping, installation, and maintenance easier — especially for rooftop and wall-mount applications.

3. Lower Cost

Without heavy copper and iron cores, BOM (Bill of Materials) cost drops significantly.

Manufacturers pass these savings to installers and end users.

4. Flexible Design

The absence of a transformer enables higher switching frequency, allowing compact design, faster response, and quieter operation.

5. Improved System Yield

Higher efficiency and optimized MPPT tracking deliver better total energy harvest over the inverter’s lifespan.

6. Challenges and Considerations

Despite clear advantages, transformerless inverters require careful system design and grounding.

1. Leakage Current Management

Without galvanic isolation, DC leakage currents can flow to ground.

→ Use RCD (Residual Current Device) and RCM monitoring to detect faults.

2. Grounding and Safety

Ensure proper grounding of PV array negative pole and frame.

Follow local codes — some regions still require galvanic isolation.

3. Compatibility with Old Systems

Retrofit projects originally designed for transformer inverters may need grounding reconfiguration or RCD upgrades.

4. Surge Protection

Add SPD Type II on DC and AC sides to protect against lightning or transient voltage spikes.

When these aspects are properly handled, transformerless inverters perform as safely as their transformer-based counterparts.

7. Applications in Energy Storage Systems

Transformerless design has now extended beyond solar into hybrid PV + battery systems.

Examples:

- Residential hybrid inverters (3–15kW): PV + storage + grid-tie

- C&I hybrid systems (30–200kW): For self-consumption and backup

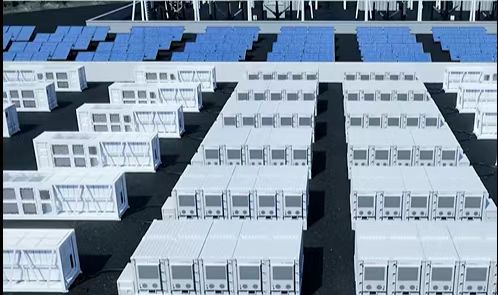

- All-in-one ESS cabinets (50–500kWh): Integrated with transformerless PCS

Benefits in Storage Applications:

- Higher round-trip efficiency (DC → AC → DC ~94–96%)

- Compact size — critical for cabinet or containerized systems

- Cost-effective for export markets

- Simpler logistics and faster installation

These inverters enable modular and scalable energy storage configurations — ideal for projects in the 10–500kWh range.

8. Technical Example

Case: 50kW Hybrid Transformerless Inverter

| Parameter | Specification |

|---|---|

| Rated AC Power | 50kW |

| PV Input | 1000V DC, dual MPPT |

| Battery Input | 600V DC max |

| Efficiency | 98.5% |

| AC Output | 400V, 3-phase |

| Isolation | Transformerless (with leakage current protection) |

| Communication | RS485 / CAN / Wi-Fi |

| Certifications | IEC 62109, UL 1741, CE |

Such an inverter can integrate a 100kWp PV system with a 200kWh LFP battery, offering high performance for small factories or commercial buildings.

9. Cost and Efficiency Comparison

| Feature | Transformer-Based | Transformerless |

|---|---|---|

| Efficiency | 94–95% | 97–99% |

| Weight (10kW) | 45–60kg | 20–30kg |

| Cost (per kW) | $180–220 | $120–160 |

| Noise | Higher (magnetic hum) | Very low |

| Maintenance | Transformer aging | Minimal |

| Application | Off-grid, old systems | Modern PV + ESS |

Savings in cost and logistics make transformerless models the global standard for export-oriented inverter suppliers.

10. Safety and Certification

To meet international export requirements, transformerless inverters must pass:

- IEC 62109-1/2 – Safety of power converters

- IEC 61727 – Grid connection requirements

- VDE 0126-1-1 – Anti-islanding protection

- UL 1741 / IEEE 1547 – U.S. grid standards

These standards ensure leakage current limits, insulation resistance, and ground fault detection meet strict safety levels.

11. Emerging Technologies

Modern transformerless inverters benefit from next-generation components:

1. SiC (Silicon Carbide) MOSFETs

- Higher voltage tolerance

- Lower switching losses

- Enables >99% peak efficiency

2. Bidirectional Design for Hybrid Systems

- Seamless switch between PV, grid, and battery modes

- Supports both AC coupling and DC coupling

3. AI-Based MPPT and Fault Diagnosis

- Real-time optimization using machine learning

- Predictive maintenance reduces downtime

These advances further push the boundaries of efficiency and reliability.

12. Practical Recommendations for Buyers

If you are sourcing or specifying inverters for PV or ESS projects:

✅ Check Certifications: IEC 62109, UL 1741, VDE 4105 compliance

✅ Confirm Efficiency: ≥97% rated, with low THD

✅ Ensure Protection: RCD, SPD, and isolation monitoring included

✅ Ask About Communication: RS485 / CAN / Wi-Fi for EMS integration

✅ Plan Grounding Properly: Follow local electrical codes for TN/TT/TN-S systems

Choosing a reliable transformerless inverter brand can directly affect system safety, energy yield, and ROI.

The move toward transformerless inverters represents a major step in the evolution of PV and storage systems.

They are:

- Lighter,

- More efficient,

- Cost-effective, and

- Ideal for hybrid integration.

For EPCs, distributors, and project developers, understanding this technology is essential to design systems that meet global standards and deliver long-term reliability.

As power electronics continue to advance — with SiC and AI-based control — transformerless inverters will remain at the core of the modern solar + storage ecosystem, enabling smarter, greener, and more profitable energy solutions worldwide.