Understanding the Promise and Challenges of Solid-State Batteries for Energy Storage Systems

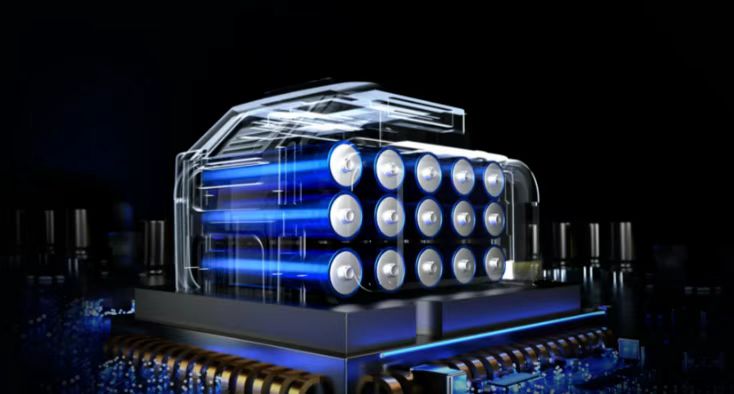

The energy storage industry is in the midst of rapid transformation. As lithium-ion batteries dominate today’s market — from EVs to residential energy storage systems (ESS) — researchers and manufacturers are already looking ahead to what might come next: solid-state batteries (SSBs).

Solid-state technology promises higher energy density, improved safety, and longer cycle life, all of which sound ideal for both electric vehicles (EVs) and stationary energy storage.

But the question remains: Is solid-state really ready for ESS applications? Let’s take a closer look at what makes these batteries different, how they work, and whether they can deliver on their promise in large-scale energy storage.

What Is a Solid-State Battery?

At its core, a solid-state battery is similar in structure to a conventional lithium-ion battery, but with one major difference:

Instead of using a liquid electrolyte, it uses a solid electrolyte.

Basic Structure

| Component | Traditional Li-ion | Solid-State Battery |

|---|---|---|

| Anode | Graphite (sometimes silicon) | Lithium metal or composite anode |

| Electrolyte | Liquid organic solvent | Solid ceramic, glass, or polymer |

| Cathode | Layered oxide (e.g., NMC) | Similar materials, often with modified interfaces |

| Separator | Porous film | Not needed (electrolyte acts as separator) |

The solid electrolyte enables the use of metallic lithium anodes, which theoretically provide up to 2–3 times the energy density of today’s batteries.

How Does a Solid-State Battery Work?

Just like a conventional battery, an SSB stores and releases energy by moving lithium ions between the anode and cathode during charge and discharge.

However, in an SSB:

- Ions move through a solid material instead of a liquid.

- The solid layer prevents dendrite formation (metal filaments that can cause short circuits).

- The lack of flammable liquid electrolyte significantly improves safety.

⚙️ In theory, solid-state batteries could achieve energy densities of 400–500 Wh/kg, compared to 250–300 Wh/kg for current Li-ion cells.

Advantages of Solid-State Batteries

1. Higher Energy Density

The use of lithium metal anodes allows for much higher capacity storage per unit mass.

For energy storage systems, this means more energy in less space — a crucial advantage for applications where space and weight matter, such as commercial rooftops or urban ESS cabinets.

2. Improved Safety

Solid electrolytes are non-flammable and thermally stable, eliminating the main fire risk associated with liquid electrolytes.

This is particularly valuable in residential and grid-scale ESS, where fire propagation in large lithium-ion installations remains a major safety concern.

3. Wider Operating Temperature Range

Many solid-state electrolytes remain stable from –20°C to over 100°C, reducing the need for complex cooling or heating systems — an advantage for remote or outdoor installations.

4. Longer Cycle Life

Because solid electrolytes reduce side reactions and dendrite growth, they may achieve >5000 charge/discharge cycles with minimal capacity fade — extending the lifespan of storage systems well beyond current Li-ion technology.

Challenges in Applying SSBs to Energy Storage Systems

Despite the promise, solid-state batteries are not yet widely commercialized for ESS.

Several technical and economic barriers remain.

1. Manufacturing Complexity

Producing a solid electrolyte with both high ionic conductivity and stable interfaces is extremely challenging.

Ceramic materials (like LLZO or sulfides) are brittle and difficult to process into thin, uniform layers suitable for large-format ESS cells.

⚠️ Current production requires vacuum sintering and dry environments, increasing cost and limiting scalability.

2. Interface Resistance

Unlike liquid electrolytes, solid materials struggle to maintain perfect contact between the anode and cathode.

Microscopic gaps can lead to increased resistance, reduced power output, and uneven ion flow, especially over long cycling periods.

This makes SSBs currently less ideal for high-power or fast-charging ESS applications.

3. Material Cost and Scalability

The materials used in solid-state batteries — such as lithium metal, ceramic oxides, and sulfide electrolytes — are expensive and often require specialized equipment.

While small-format cells for EVs and consumer electronics are entering pilot production, scaling to hundreds of kilowatt-hours for ESS remains cost-prohibitive.

💰 Current prototype SSBs can cost 2–3× more per kWh than standard LiFePO₄ or NMC-based ESS batteries.

4. Safety Trade-offs in Some Electrolytes

Not all solid electrolytes are created equal.

Some sulfide-based electrolytes release toxic gases (like H₂S) when exposed to moisture, while oxide-based materials require high fabrication temperatures.

This adds further complexity to installation, maintenance, and recycling — important considerations for stationary energy systems.

Where Solid-State Batteries Stand Today

As of 2025, most solid-state battery development remains focused on electric vehicles, led by companies such as:

- Toyota and QuantumScape (oxide electrolytes)

- Solid Power and Samsung SDI (sulfide systems)

- ProLogium and Factorial Energy (hybrid polymer systems)

For ESS applications, only a few startups and research projects — such as Blue Solutions, SolidEnergy Systems, and Taiwan’s ITRI — are exploring pilot-scale deployments.

Current prototypes for stationary storage achieve:

- Energy density: 300–350 Wh/kg

- Cycle life: 2000–3000 cycles

- Operating voltage: 3.6–4.2 V

- Round-trip efficiency: ~90%

While these numbers are promising, they don’t yet outperform mature LiFePO₄ or LTO systems in cost and reliability.

Solid-State Batteries vs. LiFePO₄ in ESS

| Feature | Solid-State (SSB) | LiFePO₄ (LFP) |

|---|---|---|

| Energy Density (Wh/kg) | 350–500 (theoretical) | 160–200 |

| Cycle Life | 3000–10000 (target) | 4000–7000 |

| Safety | Excellent (non-flammable) | Very good |

| Temperature Tolerance | Wide (–20°C to 100°C) | Moderate (0–60°C) |

| Cost ($/kWh) | 300–400+ (est.) | 100–150 |

| Commercial Availability | Pilot stage | Mass production |

In short: SSBs outperform LFP technically, but LFP wins in cost, maturity, and supply chain — making it the current ESS favorite.

When Will Solid-State Batteries Be Ready for ESS?

Most analysts expect automotive-scale solid-state production to start around 2027–2030.

ESS applications will likely follow 2–3 years later, as manufacturing scales up and costs decline.

The key developments to watch include:

- Sulfide-based electrolytes with improved air stability.

- Hybrid solid–liquid designs that combine safety and manufacturability.

- Roll-to-roll fabrication of thin solid electrolyte films.

- Recycling and end-of-life solutions tailored for solid-state materials.

If these advances succeed, commercial ESS-grade SSBs could emerge by 2030–2032, first in high-value or space-limited applications — such as aerospace, defense, or data centers.

The Role of Hybrid and Semi-Solid Batteries

Between today’s liquid Li-ion and full solid-state batteries lies a transitional category: semi-solid batteries.

These use a gel-like electrolyte, combining some advantages of both worlds:

- Better safety and reduced flammability

- Easier manufacturing than ceramics

- Improved interface contact

Companies like 24M and CATL (Condensed Battery) are pushing this hybrid approach, and it may become the practical bridge technology before true solid-state systems dominate.

Solid-state batteries represent a major leap forward in electrochemical storage, offering unmatched energy density, safety, and longevity.

However, for large-scale energy storage systems (ESS), the technology is not yet ready for mainstream deployment.

Manufacturing cost, interface challenges, and scalability still limit commercial adoption.

In the near term, LiFePO₄ and semi-solid lithium technologies will continue to dominate the ESS market, providing proven performance and affordability.

That said, as the 2030s approach, solid-state batteries are poised to become a game-changer — especially for applications demanding maximum energy density and safety.

The solid-state revolution is coming — just not quite yet.