Why PV-Inverter Matching Matters

For international buyers of energy storage systems (ESS) integrated with solar, one of the most critical technical parameters is the matching of PV modules with inverters. A mismatch can lead to efficiency losses, warranty issues, or even failed installations. Exporters who understand regional requirements and can explain PV-inverter matching effectively gain an edge in global markets.

1. What Is PV-Inverter Matching?

- Definition: The process of sizing and configuring photovoltaic (PV) modules so that their output voltage, current, and power fall within the inverter’s operating range.

- Impact: Correct matching ensures maximum energy harvest, system stability, and long-term reliability.

Exporter Tip: Always provide recommended PV-to-inverter ratios in quotations and technical datasheets.

2. General Matching Rules

- DC-to-AC Ratio: Typically between 1.1 and 1.3, meaning the PV array’s DC capacity is slightly higher than the inverter’s AC rating.

- Voltage Window: PV string voltage must stay within inverter input limits across temperature variations.

- Current Limits: String and array current should not exceed inverter maximum ratings.

Exporter Tip: Explain these rules with simple diagrams to make them clear to non-technical buyers.

3. Regional Considerations

Europe

- Focus: Compliance with EU grid codes (EN standards).

- Common Practice: Higher DC/AC ratios due to lower average solar irradiation.

- Buyer Expectation: Strong emphasis on efficiency and certification.

North America

- Focus: NEC (National Electrical Code) compliance.

- Common Practice: Conservative DC/AC ratios (around 1.1) due to strong sun in many states.

- Buyer Expectation: Safety, UL certification, and quick ROI.

Middle East

- Focus: Extreme heat performance.

- Common Practice: Derating of inverters to avoid overheating; careful string sizing for high ambient temperatures.

- Buyer Expectation: Systems proven to withstand 45–50°C environments.

Asia-Pacific

- Focus: Price competitiveness.

- Common Practice: Wide variation in matching practices; some markets push higher DC/AC ratios to cut costs.

- Buyer Expectation: Flexible, low-cost solutions.

Exporter Tip: Adapt recommendations to regional climate, regulations, and buyer priorities.

4. PV-Inverter Matching and Storage Integration

- Hybrid Inverters: Buyers increasingly ask for hybrid inverters combining PV and battery control.

- AC-Coupled vs DC-Coupled: The choice affects how PV and storage are matched.

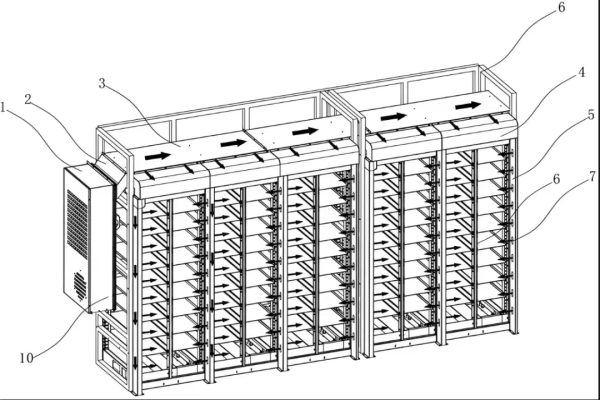

- Market Trends: Residential buyers prefer integrated solutions; industrial buyers may prefer modular systems.

Exporter Tip: Highlight how your ESS integrates seamlessly with regional inverter preferences.

5. Risks of Poor Matching

- Efficiency Losses: Wasted solar energy if inverter clips or shuts down.

- Component Stress: Over-voltage or over-current can damage hardware.

- Warranty Issues: Using non-recommended configurations may void warranties.

Exporter Tip: Position correct matching as risk reduction and cost savings.

6. How to Communicate Clearly with Buyers

- Use Case Examples: Show recommended matching for residential, commercial, and utility-scale systems.

- Regional References: Provide case studies from the buyer’s own region.

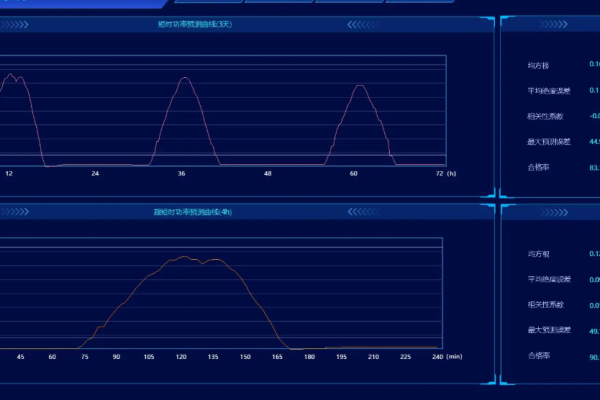

- Tools and Software: Offer design tools or simulations to verify PV-inverter sizing.

Exporter Tip: Support quotations with simulation reports to increase credibility.

Matching as a Competitive Advantage

In ESS exports, PV-inverter matching is a technical requirement and a sales opportunity. By understanding regional practices and clearly explaining compatibility, exporters can avoid disputes, speed up sales cycles, and build buyer trust. When presented with clarity and backed by data, PV-inverter matching becomes a strong differentiator in global energy storage trade.