As the energy storage industry matures, thermal management has become one of the most decisive factors in ensuring system performance, safety, and lifespan. Whether deployed in industrial parks, telecom stations, or microgrids, a poorly managed temperature environment can accelerate degradation, trigger thermal runaway, and reduce usable capacity — even in otherwise well-designed systems.

Effective thermal management design enables stable operation across temperature extremes, extending system reliability and reducing maintenance costs. This article explores practical thermal control strategies, real-world implementations, and engineering lessons from industrial-scale storage deployments.

1. Why Thermal Management Matters

Temperature directly affects every aspect of an energy storage system’s performance. In industrial environments — often exposed to dust, vibration, and ambient temperatures above 40°C — the challenge is even greater.

Key Impacts of Poor Thermal Management:

- Accelerated aging: Every 10°C rise above optimal temperature can halve battery lifespan.

- Uneven cell performance: Thermal gradients cause cell imbalance and efficiency loss.

- Safety risk: Overheating or localized hot spots increase the risk of thermal runaway.

- Reduced capacity: Cold temperatures limit ion mobility, lowering available energy.

A robust thermal system thus serves three roles simultaneously — performance stabilizer, safety barrier, and longevity enhancer.

2. Understanding Thermal Behavior in Battery Systems

Industrial energy storage systems typically operate between -20°C and +60°C, though optimal range is narrower (15°C–35°C). Within this range, the system must maintain consistent thermal conditions across all modules.

Major Heat Sources:

- Internal resistance losses during charge/discharge.

- Conversion losses in power electronics.

- Ambient radiation and solar gain in outdoor cabinets.

Cooling Objectives:

- Prevent temperature differentials exceeding 5°C between cells.

- Maintain stable operating temperature to reduce mechanical and electrochemical stress.

- Enable safe shut-down procedures if thresholds are exceeded.

3. Core Thermal Management Approaches

a) Passive Cooling

Passive cooling relies on natural convection, heat sinks, and ventilation to dissipate heat without external power consumption.

Applications:

- Small-capacity or low-C-rate systems (e.g., remote telecom towers, backup modules).

- Environments with stable ambient temperatures.

Design Elements:

- High-conductivity aluminum casings for heat dissipation.

- Internal air channels or vents for convection.

- Thermal pads or graphite sheets to spread localized heat.

Advantages: Simple, low cost, maintenance-free.

Limitations: Ineffective under high load or high ambient temperature.

Case Example:

A 10 kWh LFP module deployed in rural base stations used graphite-based heat spreaders and vented aluminum housing, maintaining cell temperature uniformity within ±3°C under full load.

b) Forced Air Cooling

Forced air systems use fans or blowers to enhance convection, improving heat transfer across modules.

Key Design Points:

- Airflow direction should follow module layout to prevent recirculation.

- Filters required in dusty environments.

- Redundant fan configuration (N+1) for reliability.

Advantages:

- Moderate cooling efficiency.

- Scalable for modular racks.

Challenges:

- Noise and power consumption.

- Limited performance at very high ambient temperatures.

Practical Insight:

Forced-air cooling is most effective when paired with intelligent fan control based on cell temperature feedback, reducing unnecessary energy use while maintaining thermal balance.

c) Liquid Cooling

For high-density or high-power systems (e.g., >100 kWh industrial batteries), liquid cooling offers precise temperature control.

System Components:

- Coolant channels or plates integrated within module frames.

- Pump, radiator, and expansion tank.

- Temperature sensors and control valves.

Advantages:

- Excellent thermal uniformity (<2°C gradient).

- Suitable for compact enclosures and high ambient temperatures.

- Enables operation at higher continuous C-rates.

Drawbacks:

- Higher system complexity and cost.

- Requires leak-proof design and long-term coolant stability.

Case Example:

In a 1 MWh factory microgrid installation, liquid-cooled modules reduced thermal stress by 40%, extending cycle life from 4,000 to 6,000 cycles and maintaining consistent power delivery at 45°C ambient temperature.

d) Phase Change Materials (PCM)

PCM-based systems absorb excess heat by melting at a specific temperature range, offering passive thermal buffering.

Benefits:

- No moving parts or active cooling requirement.

- Prevents rapid temperature rise during peak load events.

Use Case:

A modular ESS deployed in containerized telecom hubs integrated graphite-enhanced PCM panels, maintaining internal module temperature below 35°C even under full sunlight conditions.

4. Control and Monitoring Integration

A thermal system is only as good as its control and feedback loop. Integration with the BMS and EMS ensures real-time thermal optimization.

Core Control Logic:

- Temperature Sensing: Each module reports temperature at multiple cell nodes.

- Dynamic Control: Fans, pumps, or valves adjust in response to thresholds.

- Predictive Algorithms: Use historical patterns to anticipate thermal spikes.

- Fault Response: Automatic derating or safe shutdown upon critical temperature detection.

Advanced Trend:

AI-enhanced BMS now use thermal prediction models trained on operational data, enabling proactive heat management rather than reactive cooling.

5. Engineering for Reliability

Thermal management systems themselves must be robust and fault-tolerant, especially for remote industrial installations.

Design Recommendations:

- Use redundant fans/pumps (N+1 configuration).

- Ensure fail-safe operation — passive cooling backup if active system fails.

- Include manual bypass modes for maintenance or emergencies.

- Design for ease of cleaning and servicing, particularly in dusty or oily environments.

Lesson from Field Deployment:

A mining microgrid project initially suffered 20% downtime due to fan clogging. After redesigning with dust-sealed enclosures and replaceable filters, uptime improved to 99.5%.

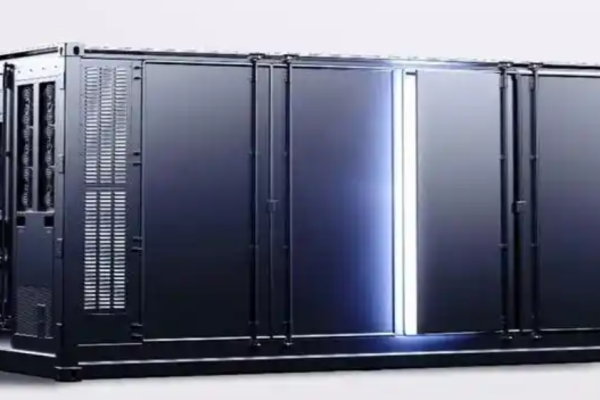

6. Integration with System Architecture

Thermal management must be considered at the system design stage, not as an afterthought. Proper layout reduces both complexity and failure risk.

Integration Guidelines:

- Align air or coolant flow direction with module stacking orientation.

- Minimize thermal cross-talk between battery, inverter, and transformer zones.

- Include thermal expansion gaps to prevent mechanical stress.

- Integrate thermal monitoring data directly into EMS dashboards for operator visibility.

Example:

A modular 500 kWh system separated inverter and battery compartments with thermal partitions and independent cooling loops — lowering system temperature differential from 12°C to 4°C during peak operation.

7. Safety Standards and Validation

Industrial ESS thermal designs must comply with both electrical and safety standards:

- UL 9540A: Thermal runaway and fire propagation testing.

- IEC 62619: Safety requirements for lithium battery systems.

- NFPA 855: Installation and thermal safety in ESS deployments.

- IEC 62933-5-2: Test methods for performance and temperature management.

Validation Testing:

- Heat rise and temperature uniformity mapping.

- Fan/pump endurance testing.

- Thermal shock and cold-start performance.

- Emergency thermal event simulations.

Takeaway:

Rigorous validation prevents unexpected failures and simplifies insurance and certification approval.

8. Case Study: Thermal Optimization in a 250 kWh Modular ESS

Project Overview:

- Application: Factory energy peak shaving

- Configuration: 5 × 50 kWh liquid-cooled modules

- Ambient: 38°C (summer average)

- Cooling: Closed-loop liquid system with intelligent pump control

Results:

- Average cell temperature: 33°C

- Temperature difference between modules: <2.5°C

- System efficiency gain: +3.8% (due to reduced internal resistance)

- Maintenance interval extended by 30%

Key Lesson:

Intelligent, closed-loop liquid cooling delivers measurable lifecycle gains and enhances system uptime — especially under continuous industrial operation.

9. Best Practices Summary

| Objective | Recommended Strategy |

|---|---|

| Small-scale or remote systems | Passive or forced-air cooling |

| High-density industrial ESS | Liquid or hybrid cooling |

| Harsh outdoor conditions | Sealed enclosure + PCM or liquid loop |

| Maintenance priority | Modular fan/pump design for easy replacement |

| Long-term reliability | Predictive thermal monitoring via EMS |

Thermal management is the unsung hero of system reliability in industrial energy storage. A well-designed cooling strategy ensures consistent performance, safety, and long service life, while also reducing downtime and operational costs.

As industrial and commercial storage systems scale, the next generation of designs will integrate AI-driven predictive thermal control, smart redundancy, and modular cooling architectures — turning temperature control from a passive safeguard into an active performance enhancer.