Why Heat Management Is Critical for System Longevity and Safety

1. Why Thermal Design Matters in Energy Storage

Energy storage systems (ESS) are sensitive to temperature. In hot climates, poor heat management leads to:

- 🔋 Battery degradation (especially lithium-ion cells)

- ⚠️ Inverter derating or shutdowns

- 🔥 Fire hazards from thermal runaway

- 📉 Reduced cycle life and poor ROI

Small-scale ESS projects—such as residential setups or compact commercial cabinets—often lack dedicated cooling, making thermal design a silent risk factor.

In this article, we explore practical design principles for building thermally stable ESS cabinets in high-temperature regions.

2. Typical Challenges in Hot Climates

Hot environments (ambient > 35°C) create multiple risks:

| Risk | Impact |

|---|---|

| High battery temps (>40°C) | Faster aging, capacity loss |

| Poor ventilation | Hotspots, uneven temperature distribution |

| Enclosure overheating | Device shutdown, inverter faults |

| No airflow design | BMS overwork, safety shutdowns |

| Direct sunlight exposure | Cabinet surface reaches 60°C+ |

3. Understanding Heat Sources in ESS Cabinets

Heat doesn’t only come from the weather. A typical small ESS cabinet generates internal heat from:

- 🔋 Battery pack(s): 1–2% of stored energy turns to heat during charge/discharge

- 🔄 Inverter operation: 3–5% energy loss as heat, especially at full load

- 📟 BMS, EMS, gateway electronics

- ☀️ External solar radiation, especially for outdoor installations

In a 10 kW inverter + 20 kWh battery system, the cabinet could release 200–400 W of heat continuously under full load.

4. Best Practices for Thermal Management

🌬️ Passive Ventilation (for Moderate Heat Zones)

- Use vent slots with dust filters (top & bottom) to create convection airflow

- Place battery/inverter components to allow vertical air movement

- Avoid tight enclosures with zero airflow

✅ Low cost

❗ Not enough in very hot or humid climates

🧊 Active Cooling (Hot Climates or Heavy Loads)

- Install DC fans or thermostatic exhaust fans

- Use temperature-controlled ventilation units (e.g. PTC fans or TEC coolers)

- For outdoor cabinets, insulated metal housings with heat-reflective paint help reduce solar gain

✅ Effective in most cases

❗ Add power consumption and complexity

❗ Fans must be filtered and protected from dust/water

🧱 Enclosure Design Considerations

- Avoid black or dark-colored cabinets—use light gray or white to reflect heat

- Add ventilation louvers at the top and base

- Install in shaded areas, not direct sun

- Ensure minimum 30–50 mm air gap around internal devices

- Keep batteries away from inverter heat sinks (don’t stack tightly)

🧪 Temperature Monitoring and Alarms

- Equip the cabinet with at least 2 temp sensors:

- One at battery module surface

- One at inverter exhaust or cabinet ceiling

- Integrate alarm trigger (>45°C) to notify user

- Consider logging temperature via EMS or remote gateway for diagnosis

5. Practical Thermal Design Cases

🏠 Residential Outdoor Storage (5–15 kWh)

- Cabinet in shaded patio or wall-mounted under eaves

- Louvered passive vents + heat-resistant housing

- Optional small DC fan for summer months

- Battery spacing for airflow, bottom to top

🏢 Small Business ESS (20–50 kWh)

- Floor-standing cabinet indoors or semi-outdoor

- Internal fan + external exhaust fan

- Compartmental layout: battery zone and inverter zone

- Shielded cabling and separated thermal zones

🏜️ Extreme Hot Climates (>40°C ambient)

- Fully enclosed outdoor-rated cabinet with insulation lining

- Hybrid cooling: fans + active TEC/Peltier elements

- Scheduled inverter load reduction at peak temperature

- Redundant thermal sensors and alerts to EMS

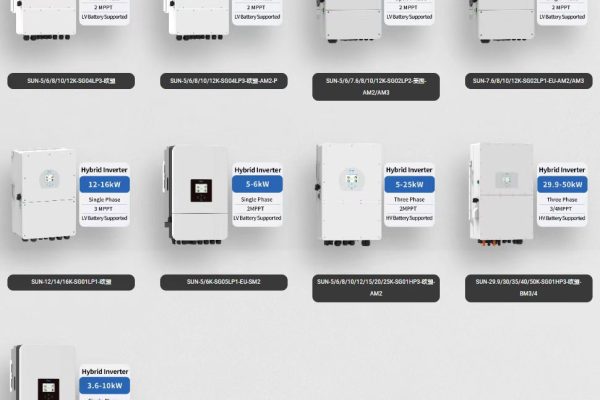

6. What a Technical Trade Partner Can Offer

Clients may underestimate the importance of cabinet temperature. As a trusted technical supplier, you can:

- 💡 Propose pre-designed thermal-ready cabinets

- 📐 Offer cabinet layout guidance with cooling flow paths

- ⚠️ Help clients choose low-loss inverters and batteries for high-temp zones

- 🛠️ Include optional cooling kits (fan, sensor, relay, etc.) in offer packages

- 🧾 Provide temperature specs and simulations on request

This kind of foresight is what makes clients trust you—not just as a seller, but as a real system partner.

7. Recently Published Articles You May Like

- 👉 Building a Compact Energy Storage Room: Tips & Layout Ideas

- 👉 Multi-day Backup with Storage: Realistic or Overkill?

- 👉 Integrating EV Charging with Residential Battery

8. Conclusion

Small energy storage cabinets must not ignore heat—especially in regions where summer temperatures soar. Smart thermal design isn’t expensive, but it protects your investment, avoids warranty claims, and builds long-term system reliability.

As a technical trade partner, your ability to plan for heat is part of the value you bring to every project.