How to Justify Investment in Energy Storage for Facilities Consuming 50kWh–500kWh Daily

Energy storage is no longer just a high-tech solution for large industrial players or solar farms. For small factories, especially those facing rising electricity costs, poor grid stability, or expanding renewable use, C&I (Commercial & Industrial) storage is becoming a viable investment — if it’s sized and priced right.

In this article, we break down how to assess the economic value of energy storage in small factory environments, and where storage makes sense (and where it doesn’t).

1. What Drives Storage ROI in Small Factories?

C&I storage pays back through multiple pathways — but not all are relevant for small facilities. Here are the main value drivers:

✅ Time-of-Use (TOU) Arbitrage

Factories on TOU tariffs can store power when it’s cheap and discharge during peak-rate periods. If the peak window is 4–6 hours and the differential exceeds $0.10/kWh, ROI improves significantly.

✅ Demand Charge Management

Some grids apply monthly demand charges based on the highest 15–30 minute usage. A properly sized battery can shave these peaks and lower monthly bills by 10–30%.

✅ Backup Power / Continuity

For factories that suffer production losses due to blackouts (e.g., refrigeration, welding, automation), the loss avoidance value of a backup system is measurable.

✅ Renewable Integration

If the facility already has solar but struggles to self-consume the energy during working hours, storage improves solar utilization and increases the effective ROI of existing PV.

2. Typical Load Profile of Small Factories

| Parameter | Typical Value |

|---|---|

| Daily Consumption | 50–500 kWh |

| Peak Load (kW) | 15–80 kW |

| Operating Hours | 8–16 hours/day |

| Load Pattern | Consistent daytime or split shift |

| TOU Tariff Availability | Common in urban & semi-urban |

| Diesel Generator Present? | Often, as backup |

🧩 A typical “sweet spot” factory may consume ~200kWh/day with a 30–40kW peak. For such loads, a 20–100kWh battery plus a 15–50kW hybrid inverter can offer real returns.

3. CapEx Overview: What Does a System Actually Cost?

Let’s break down rough price ranges for a turnkey storage system (excluding PV):

| Component | 30kW / 60kWh System (Example) |

|---|---|

| Li-ion Battery (LFP) | $14,000–$18,000 |

| Hybrid Inverter | $6,000–$9,000 |

| Cabinet / Rack | $2,000–$3,000 |

| Cables / Protections | $1,000–$2,000 |

| Installation / Labor | $3,000–$5,000 |

| Total | $26,000–$37,000 |

🧮 Annual savings of ~$4,000–$6,000 would result in payback in 5–7 years — better if incentives or local rebates are available.

4. Storage Alone or PV + Storage?

If the factory already has rooftop solar, adding storage:

- Reduces export losses where net metering is limited

- Increases self-consumption

- Adds backup capability

But even without solar, storage alone can make sense:

- In areas with high TOU differential or unstable grids

- For diesel offset during brief outages

- To protect sensitive machinery during voltage dips

💡 Pro Tip: Many projects see better ROI starting with a hybrid inverter + battery, then add solar later when budget or roof space permits.

5. Practical Deployment Models

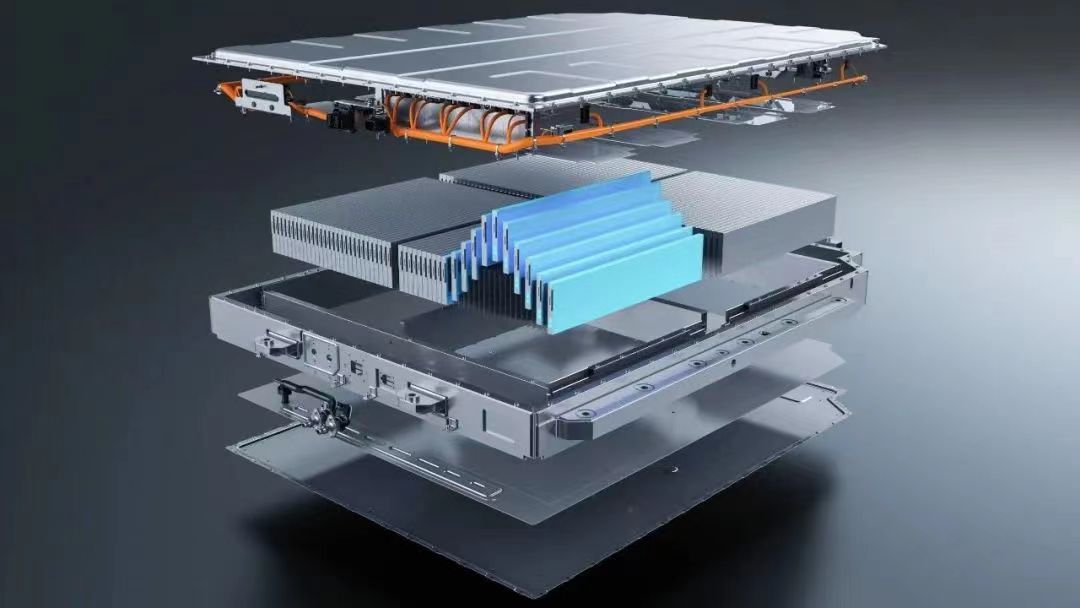

A. Cabinet-Type ESS (Indoor/Outdoor)

- Ideal for factories with limited indoor space

- Pre-integrated options reduce installation time

- Supports modular expansion (e.g., start with 60kWh, grow to 120kWh)

B. Rack-Based Systems (Technical Rooms)

- Good for indoor plant rooms or workshops

- Custom-configured for tighter budgets

- Better long-term serviceability

C. All-in-One Inverter + Battery Units

- Lower CapEx and footprint

- Faster install but less flexible

- Ideal for first-time adopters or <50kWh use cases

6. Avoiding Overdesign: What’s Enough?

Small factory buyers often overestimate their need — aiming for 100% backup or full load offset. But this often kills ROI.

✔ Instead, start with:

- 20–40% of daily usage

- 2–4 hours of peak shaving

- Backup for essential loads only (e.g., refrigeration, CNC, pumps)

📌 Example:

A welding workshop using 300kWh/day can often optimize with a 40kWh battery + 30kW inverter covering peak windows and critical tools — at a fraction of the full-site storage cost.

7. How to Build Trust When Proposing C&I Storage

As a system buyer or integrator, you’ll face concerns like:

- “Will it work during my specific peak hours?”

- “What happens if a battery fails?”

- “How long will the payback really be?”

- “Can we expand later if our loads grow?”

You earn trust by:

- Providing real-world examples (see below)

- Showing load simulations with local TOU rates

- Offering modular options, not just “one big quote”

- Making service & warranty support clear and accessible

Summary: Is C&I Storage Worth It for Small Factories?

| Factor | Impact |

|---|---|

| TOU tariff differential | 📈 Strong ROI driver |

| Frequent grid issues | 📈 Adds resilience value |

| Diesel offset potential | 📈 High fuel savings |

| PV installed or planned | 📈 Better solar ROI |

| High peak loads or demand charges | 📈 Reduces monthly bills |

✔ If at least two of the above apply, storage can likely be justified.