Understanding and Avoiding a Hidden Risk in PV + Storage System Integration

1. Introduction

In PV + energy storage projects — especially in small commercial or hybrid residential systems — one critical and often overlooked issue is the voltage window mismatch between components.

Clients often focus on capacity (kWh), power (kW), and price. But when batteries and inverters don’t operate in compatible voltage ranges, the result can be poor system performance, early degradation, or even total failure.

As a technical trading partner, understanding voltage window compatibility is essential to help your clients avoid hidden pitfalls and ensure stable operation.

2. What Is Voltage Window Mismatch?

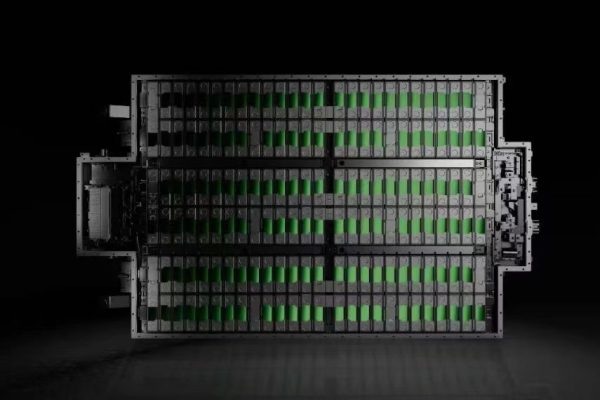

Each component in a storage system — especially the battery and the inverter — operates within a specific DC voltage range. This range is often called the “voltage window.”

For example:

- A hybrid inverter might operate between 120V–500V DC.

- A battery pack might have a nominal voltage of 204V, but its charge/discharge window could be 180V–240V.

A mismatch occurs when the battery’s voltage range doesn’t fall within the inverter’s acceptable input range — or overlaps only partially.

3. Why This Happens in Real Projects

1. Off-the-shelf battery + inverter pairing

Buyers may purchase batteries and inverters from different brands without checking voltage compatibility.

2. Poor communication between suppliers

A project may involve multiple suppliers — a battery maker, an inverter vendor, and a contractor — none of whom check system-level compatibility.

3. Assuming “48V” means plug-and-play

In low-voltage systems (e.g., 48V nominal), actual charge/discharge voltages may range from 42V to 58V — and some inverters can’t track the full range.

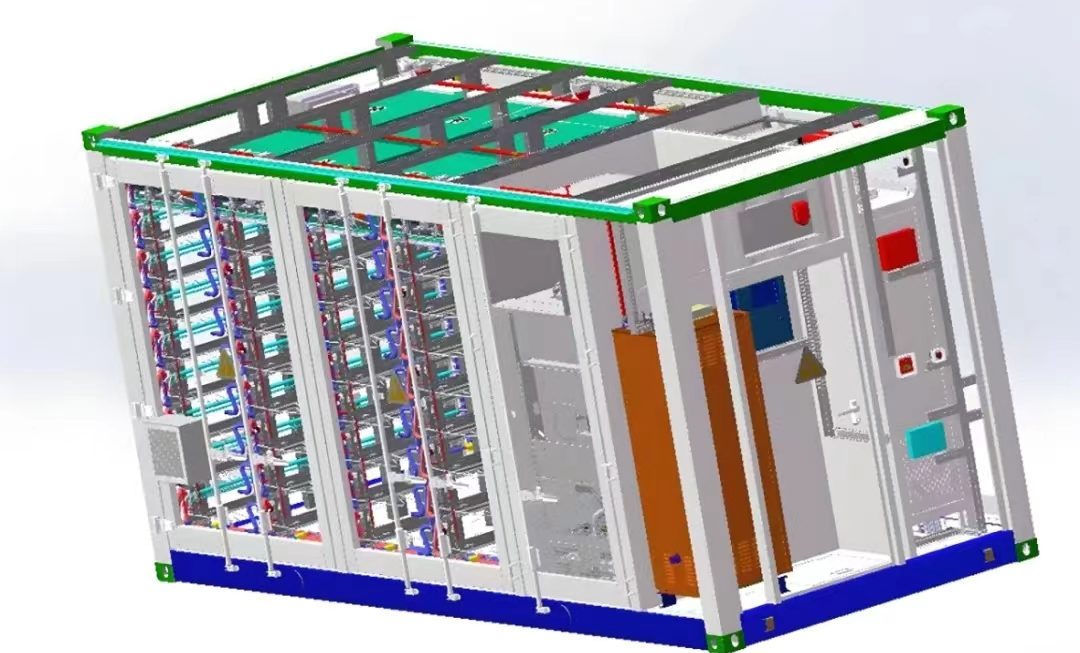

4. Improper pack configuration

In custom BESS cabinets, if cells/modules are connected in series improperly, it shifts the total system voltage outside the inverter’s expected range.

4. What Can Go Wrong?

A voltage mismatch doesn’t always show immediate failure — but it almost always causes long-term performance problems.

Common Issues:

- Inverter not starting because the battery voltage is too low at boot

- Charging never reaching full capacity due to cutoff voltage limits

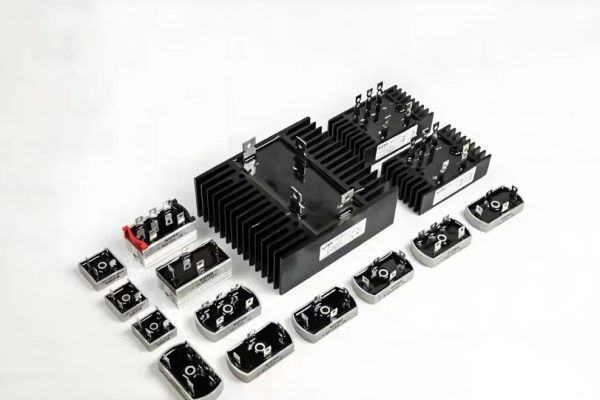

- Excessive heat or stress on components during conversion

- Frequent shutdowns or alarms under load

- Accelerated battery degradation from operating outside optimal voltage

This leads to:

- More service calls

- Lower customer satisfaction

- Shorter product lifespan

- Warranty conflicts

5. Matching the Voltage Window: What to Check

✅ Inverter Specs:

- MPPT voltage range

- Startup voltage

- Battery input range (for hybrid models)

✅ Battery Specs:

- Nominal voltage

- Charge/discharge cutoff voltages

- Recommended operating range (to preserve cycle life)

✅ Actual Configuration:

- For modular systems: Check how many cells or modules in series.

- Consider voltage drop due to cable length or environment.

6. Use Case Example: 20kWh Storage + 10kW Hybrid Inverter

Scenario:

A client wants to install a 10kW hybrid inverter (DC range: 180V–500V) with a 20kWh cabinet battery pack.

Battery configuration:

Uses LFP cells, nominal 3.2V per cell. 60 cells = 192V nominal, 168V min, 219V max.

Result:

- Startup voltage (180V) > battery’s actual low voltage (168V)

- Inverter fails to start under cold/discharged conditions

- System underperforms unless battery voltage stays artificially high

Fix:

- Change battery to 64-cell configuration (204V–262V)

- Or choose inverter with 150V startup voltage

7. How to Avoid Voltage Mismatch

As a trusted partner, you can help clients avoid this risk by offering design review support before procurement. Key steps include:

✅ Standardize Compatible Packages

Offer predefined inverter + battery combos that are fully tested and matched.

✅ Confirm Specs Before Shipping

Always check the actual voltage window in datasheets — not just nominal voltage.

✅ Share Basic “Voltage Matching” Guide

Create a simple visual or table to help clients understand voltage ranges at a glance.

✅ Support Commissioning

If clients use their own installer, offer to review the SLD (Single Line Diagram) and confirm voltage ranges as part of pre-shipment support.

8. Value You Offer as a Technical Supplier

Typical trading companies may ignore or not understand voltage mismatch — leading to frustrated installers and clients.

Your technical edge:

- Early prevention, not post-sales troubleshooting

- Guidance on battery series count

- Matching inverters by application scenario (residential, off-grid, C&I)

- Avoiding warranty issues related to improper voltage usage

This professional approach builds trust and long-term partnerships, especially with first-time buyers or small EPCs.

9. Recently Published Articles (Internal Links)

- 👉 How to Guide the Client Through a 3kW/5kW/10kW System Decision

- 👉 What Is the Difference Between String Inverters and Microinverters?

- 👉 Common Questions from First-Time ESS Buyers

10. Conclusion

Voltage window mismatch is one of the most frequent — yet preventable — causes of underperformance in PV + storage projects. Especially in flexible, small-scale systems, your ability to identify and resolve this challenge adds real value.

By offering early-stage checks, practical design suggestions, and pre-matched solutions, you ensure that your clients avoid costly installation delays, performance losses, and after-sales frustration.

Be the partner who makes their system work — not just the one who ships boxes.