How to Ensure Safe and Smart Battery Operation in PV+Storage Systems

As battery storage becomes a core component of residential and light C&I solar projects, ensuring seamless integration between the Battery Management System (BMS) and the hybrid inverter is more important than ever. A poorly connected BMS can result in charging failures, inverter errors, or even damage to the battery system.

This guide provides a practical, system-level view for EPC contractors, technical traders, and solar system integrators working with lithium batteries and hybrid inverters.

🔋 What Is a BMS and Why Does It Matter?

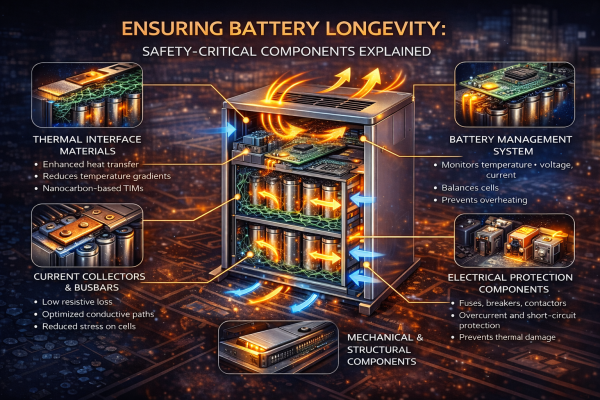

The Battery Management System (BMS) is the brain of a lithium battery. It controls, monitors, and protects the battery cells by:

- Regulating charging and discharging currents

- Monitoring temperature, voltage, and State of Charge (SOC)

- Balancing cells for lifespan and performance

- Issuing warnings or shutdown commands when safety limits are breached

Without proper BMS-inverter communication, your hybrid inverter may not follow safe charging protocols—putting system reliability and safety at risk.

🧩 What Does “BMS–Inverter Integration” Involve?

A properly integrated system allows two-way communication between the hybrid inverter and the BMS. This enables:

| Communication Flow | Purpose |

|---|---|

| BMS → Inverter | SOC %, voltage, current, temp, alarms |

| Inverter → BMS | Charging/discharging commands, status confirmation |

The connection is typically established via RS485, CAN bus, or Modbus protocols using a communication cable or through a dedicated port.

🔌 Common Physical Interfaces

| Interface Type | Description | Use Case |

|---|---|---|

| RS485 | Serial communication; popular for Modbus RTU | Older systems or basic LFP packs |

| CAN Bus | Fast, robust; used by most advanced lithium BMS systems | Mainstream for LFP and NMC systems |

| Modbus TCP | Ethernet-based protocol for larger or smarter BMS units | C&I projects or remote control setups |

🔧 Tip: Always verify the PIN definition and baud rate from both inverter and battery datasheets before wiring.

📋 Step-by-Step: How to Connect a BMS to a Hybrid Inverter

✅ Step 1: Check Compatibility

- Confirm the battery brand/model is listed in the inverter’s compatible BMS list

- If not, ask for open protocol support or request a custom CAN profile

✅ Step 2: Prepare Communication Cable

- Use shielded twisted-pair cables

- Keep wire length within recommended distance (usually <10m)

- Follow correct PIN mapping from manuals (e.g., CAN-H, CAN-L, GND)

✅ Step 3: Set Communication Parameters

- Match baud rate, protocol type, and address ID

- Configure via the inverter’s LCD menu or installer app

✅ Step 4: Verify Status and Function

- Check inverter screen or app for:

- “Battery Connected”

- SOC % displaying correctly

- Charge/discharge power active

- No alarms from “communication loss”

⚠️ Common Issues and How to Fix Them

| Problem | Possible Cause | Solution |

|---|---|---|

| No communication | Wrong protocol or wiring | Double-check protocol and PIN definitions |

| Incorrect SOC shown | Non-matching battery profiles | Load correct battery model firmware |

| Inverter not charging battery | BMS limiting current or in protection mode | Check BMS status via battery app/logs |

| Overcharging / undervoltage | No BMS control | Use only BMS-compatible inverters |

💡 When to Use “Battery Protocol” vs. “User-Defined” Mode

- Battery Protocol / Auto Mode:

- Choose this when using a listed brand/model from the inverter menu

- The inverter loads a pre-tested BMS profile automatically

- User-Defined or Manual Mode:

- Use when battery is not on the compatibility list

- Requires you to manually set:

- Max charge/discharge current

- Cut-off voltages

- Temp limits (if allowed)

🚫 Caution: User-defined settings may bypass BMS logic. Avoid unless you understand the battery’s behavior.

🧠 Best Practices for Safe & Stable Operation

- Always ground communication shields to reduce EMI

- Isolate battery and inverter grounds if manufacturer recommends

- Use firmware-matched components for both inverter and battery

- Document all wiring and config settings for future troubleshooting

- Test under full load after commissioning

📦 For Traders and EPCs: Questions to Ask Suppliers

- Does your hybrid inverter support CAN, RS485, or both?

- Is there a list of compatible battery brands and models?

- Can you provide the BMS communication protocol file (.dbc or .xls)?

- Is firmware upgrade support available for new battery profiles?

- Can you share case studies or test results with 3rd-party batteries?

Connecting a BMS to a hybrid inverter isn’t just a wiring task—it’s a critical system integration step. Doing it right ensures accurate SOC, smart charge control, and long battery life. Whether you’re supplying equipment or designing systems, mastering this connection will improve project stability and reduce after-sales headaches.