Choosing the Right Chemistry for Your Project Risk Profile

Introduction: Not All Lithium Batteries Are Created Equal

When selecting batteries for a commercial storage system — especially between 20kWh and 500kWh — the chemistry choice often comes down to:

LFP (Lithium Iron Phosphate) vs. NMC (Nickel Manganese Cobalt)

Both are classified as lithium-ion, but they differ significantly in:

- Safety behavior under stress

- Energy density and footprint

- Temperature tolerance

- Lifecycle and long-term cost

- Regulatory compliance in indoor or sensitive environments

This article explores how to make an informed decision between LFP and NMC for small to medium commercial storage systems, such as:

- Small factories

- Commercial rooftops

- Cold chain warehouses

- Telecom or microgrid infrastructure

- Agriculture and logistics depots

1. Quick Chemistry Overview

| Parameter | LFP | NMC |

|---|---|---|

| Nominal Voltage (per cell) | 3.2V | 3.6–3.7V |

| Energy Density | Lower (90–140 Wh/kg) | Higher (150–220 Wh/kg) |

| Thermal Stability | High (safe at >250°C) | Moderate (risk above 200°C) |

| Cycle Life (typical) | 4000–6000+ | 2000–3000 |

| Cost per kWh (cell) | Slightly higher | Slightly lower |

| Degradation Rate | Slower | Faster |

| Common Use | ESS, buses, backup systems | EVs, compact mobile storage |

2. Safety: The #1 Differentiator for Stationary Use

In commercial or semi-industrial applications, safety is paramount. Systems are often deployed:

- Indoors or in enclosed rooms

- Near personnel or sensitive inventory

- With limited space for active fire protection

LFP is the safer choice in nearly all cases:

- Non-thermal runaway prone under overcharge or physical abuse

- Slower reaction to high heat

- Self-extinguishing behavior under internal short

In contrast, NMC can propagate fires quickly if not perfectly managed. This matters in storage cabinets, containerized systems, or rural deployments with limited fire response infrastructure.

Verdict:

If safety or fire regulations are strict, LFP is often the default recommendation.

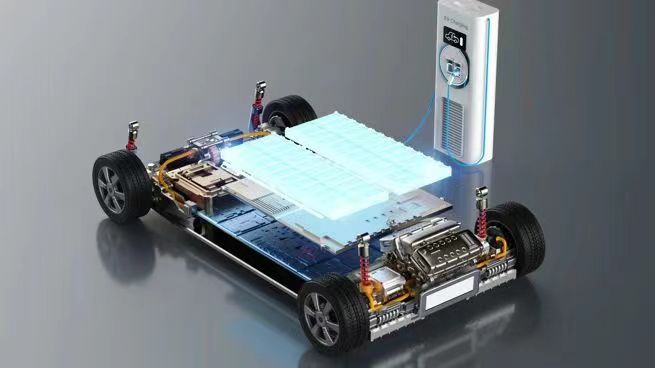

3. Energy Density: When Space Is Tight

NMC offers higher energy per unit volume and weight, which matters if:

- The system is mobile or vehicle-mounted

- You’re fitting batteries into space-constrained indoor cabinets

- Weight constraints apply (e.g., rooftop or telecom tower)

In a 100kWh system:

- LFP may require ~3.5–4 m³ cabinet volume

- NMC can achieve it in ~2.5–3 m³

However, with modern rack and container designs, this gap is narrowing.

Verdict:

If space is extremely limited and safety systems are robust, NMC has an edge.

4. Cost and Lifecycle Considerations

LFP generally has a longer cycle life and lower degradation rate over time — meaning it can deliver more energy over its life, even if the initial cost per kWh is slightly higher.

| Metric | LFP System | NMC System |

|---|---|---|

| Initial cost (20–100kWh) | ~$280–350/kWh | ~$260–320/kWh |

| Expected cycles (80% DoD) | 5000+ | 2500–3000 |

| Effective energy cost ($/kWh over life) | Lower (due to lifespan) | Higher (shorter life) |

In hot climates, NMC degradation accelerates, while LFP tolerates higher temperatures better.

Verdict:

For projects with daily cycling and a 5–10 year target lifespan, LFP gives better long-term value.

5. Compliance and Insurance

As fire-related incidents rise, local regulators and insurers increasingly favor LFP:

- In some European and Southeast Asian regions, only LFP is permitted indoors.

- For BESS in critical infrastructure or public buildings, compliance favors LFP, due to its lower thermal propagation risk.

Even if NMC is cheaper upfront, the cost of compliance upgrades (ventilation, fire doors, suppression systems) may negate savings.

6. Which Projects Might Still Use NMC?

NMC may still be relevant in:

- Mobility-focused applications (e.g., mobile trailers, battery carts)

- Temporary or seasonal deployments where compactness matters more than longevity

- Clients highly constrained on space but open to increased protection cost

In these cases, ensure:

- Advanced BMS with cell-level monitoring

- Fire suppression integration

- Proper ambient cooling and spacing

- Compliance with UL9540A or IEC 62619/62933 standards

7. Questions to Ask Before Choosing

As a project buyer or integrator, ask:

- Will the system run daily or only for backup?

- Is indoor deployment required?

- Is the site in a hot climate zone (≥35°C ambient)?

- Are insurance or permitting requirements strict?

- Do we have space for LFP racks or containers?

- How important is future expandability or cycling depth?

If safety, heat tolerance, and lifecycle matter more than compactness — choose LFP.

If every cm counts and you can afford extra protection — NMC is an option.

Summary: LFP Is the Default for Commercial ESS — For Good Reason

| Criteria | Best Choice |

|---|---|

| Fire safety | ✅ LFP |

| Indoor installation | ✅ LFP |

| Budget backup only | ✅ LFP |

| Space-constrained | ✅ NMC |

| Extreme climates | ✅ LFP |

| High daily cycling | ✅ LFP |

| Portable or mobile | ✅ NMC |

LFP is now the default chemistry for most commercial storage integrators, especially those building cabinet or containerized systems between 50–500kWh.

As a technical trade partner, your role is to match battery chemistry to project constraints, not just quote specs. Understanding the safety trade-offs and lifecycle costs gives your client peace of mind — and positions you as more than just a supplier.