How to Ensure Stable, Safe, and Smart Battery-Inverter Matching

Introduction: Lithium Batteries Are Not Just Plug-and-Play

As lithium batteries become the default choice for home and small C&I storage systems, many buyers assume that any hybrid inverter can work with any battery — but real-world integration is far more complex.

- Different protocols, charging algorithms, and voltage windows

- Closed vs. open BMS

- Inverter firmware compatibility

- Battery brand whitelisting

A mismatch can lead to:

- BMS alarms or shutdowns

- Undercharging or overcharging

- Communication errors

- Warranty voids

This article outlines how lithium batteries and hybrid inverters can be integrated effectively in 3–100kW PV+ESS systems, and what system buyers should check before procurement.

1. Understanding the Core Components

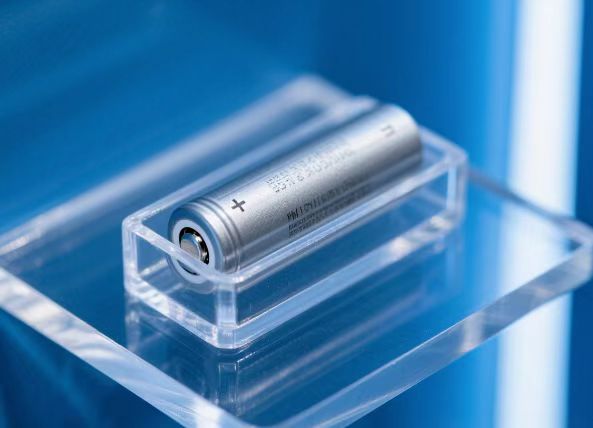

🔋 Lithium Battery

- Typically LiFePO₄ or NMC chemistry

- Has an onboard Battery Management System (BMS)

- BMS manages voltage, current, SOC, temperature, etc.

- May support RS485, CAN, or both for communication

⚡ Hybrid Inverter

- Controls PV input, AC output, and battery charge/discharge

- Communicates with BMS to coordinate charging

- Different brands use different comm protocols and pin definitions

Key Rule: Lithium batteries must talk to the inverter via matching protocols and message maps — this is NOT guaranteed by just “voltage compatibility”.

2. Communication Modes: Protocol Matching

There are typically two communication approaches:

✅ Protocol-Based (Smart) Integration

- Battery BMS communicates with inverter via CAN or RS485

- Inverter adjusts charge/discharge based on BMS instructions

- Often listed in “compatible battery list” of inverter brand

⚠️ Voltage-Control (Basic) Integration

- Inverter controls battery purely by voltage window

- No comms between BMS and inverter

- Suitable only for basic off-grid use or emergency backups

| Feature | Protocol-Based | Voltage-Control Only |

|---|---|---|

| SOC accuracy | ✅ Yes | ❌ Estimated |

| Safety (over-temp, cutoff) | ✅ Coordinated | ❌ Relies on default cutoffs |

| Warranty compatibility | ✅ Supported setups | ❌ Often excluded |

Always choose protocol-based integration for long-term reliability and smart operation.

3. Matching Battery and Inverter Brands

🧩 Check Compatibility List

Most hybrid inverter brands publish certified compatible batteries.

Example:

- Deye 5kW supports Pylontech, BYD, SOK, Dyness

- Growatt SPF series supports Shoto, Weco, and HRESYS

- Victron inverters work with batteries supporting Victron CAN protocol

If the battery you want to use is not on the list, you have three options:

- Contact the inverter manufacturer for manual integration guidelines

- Ask the battery vendor for CAN protocol documentation

- Use voltage-control mode (not recommended for large systems)

4. Common Issues in Battery-Inverter Pairing

| Issue | Cause | Fix |

|---|---|---|

| No communication | Wrong CAN wiring / pinout mismatch | Check pin definition and cable spec |

| SOC not updating or stuck at 0% | Unmatched protocol / firmware incompatibility | Update firmware or use custom protocol settings |

| Battery not charging | Inverter ignores BMS limit | Verify charge current / voltage handshake |

| Shutdown during high load | Overcurrent due to missing BMS limit sync | Lower discharge current or fix CAN comm |

Tip: Use batteries with open BMS or well-documented CAN profiles if integrating with lesser-known inverter brands.

5. Best Practices for System Buyers

✅ Choose Battery + Inverter as a Matched Set

Buy battery and hybrid inverter from the same supplier or ensure they’ve been tested together.

✅ Confirm Wiring and Protocol Details

CAN and RS485 pinout varies by brand. Use manufacturer diagrams and avoid guessing. Reversing CAN High and Low can prevent communication entirely.

✅ Check Charge/Discharge Limits

Some batteries advertise high peak current, but BMS may cap it — always check:

- Max continuous charge/discharge

- Peak surge support (seconds)

- Depth of Discharge (DoD) allowed in firmware

✅ Test Before Scaling

If using an unusual combination, test one set first and verify:

- Charging behavior

- SOC tracking

- Alarms and cutoff

- EMS communication (if used)

6. Use Case Examples

| Application Type | Suggested Pairing | Notes |

|---|---|---|

| Home hybrid backup | Deye 5kW + Pylontech US2000 | Plug-and-play via CAN |

| Off-grid cabin | Victron MultiPlus + SOK 48V | Manual CAN config with Victron Cerbo |

| Small C&I PV+ESS | Solis RHI + BYD LVL Battery Box | Tested integration via RS485 |

| Budget residential system | Growatt SPF + HRESYS 5kWh | Basic protocol via RS485 |

7. What Installers and Distributors Should Provide

To help buyers avoid integration issues, suppliers should:

- Publish clear battery compatibility lists

- Offer pre-programmed inverters or BMS if selling kits

- Provide wiring diagrams with CAN/RS485 labels

- Support firmware upgrade tools for field service

This becomes especially important for overseas buyers or those assembling systems remotely.

Conclusion: It’s About Communication, Not Just Chemistry

Integrating lithium batteries with hybrid inverters requires more than just matching voltage and capacity.

The real success factor lies in protocol compatibility, wiring accuracy, and BMS coordination.

For smooth installations and long-term performance:

- Avoid “guesswork” integration

- Prefer protocol-based communication

- Choose brands with proven cross-compatibility

- Document all settings and firmware used

This is where technical-oriented suppliers and distributors can add real value — by helping system buyers get the battery-inverter pairing right the first time.