How to Combine Diesel Generators with Storage for Smarter Off-Grid Power

In regions with weak or no grid, diesel generators have been the go-to power solution for decades. But relying solely on diesel has its problems: high fuel costs, noise, emissions, and poor energy efficiency — especially at low load.

Today, hybrid diesel-battery systems offer a smarter alternative, allowing operators to cut diesel runtime by 50–70% while maintaining power reliability. In this article, we’ll explore how to plan and deploy small-scale hybrid systems (typically 10–100kWh) for commercial and rural users.

Why Combine Diesel and Batteries?

Diesel gensets are reliable but inefficient — especially when running at partial load for long hours. That’s where batteries come in:

| Problem with Diesel Alone | Hybrid Battery Solution |

|---|---|

| High fuel use at low load | Run genset at full efficiency, store excess |

| Frequent genset cycling = wear | Let battery handle small, variable loads |

| Noise and emissions 24/7 | Battery covers night/silent hours |

| Inability to absorb solar power | Battery stores PV, reducing diesel need |

👉 Result: Diesel runs less often, at optimal efficiency, while batteries serve as a dynamic buffer.

Typical Applications for Hybrid Systems

Hybrid setups are ideal in any setting where grid is weak, unreliable, or absent — especially where diesel is already being used:

- 🧱 Construction sites (temporary but heavy demand)

- 🚜 Rural farms and water pumping (seasonal loads)

- 🏕️ Remote resorts or camps (silent operation needed at night)

- 📡 Telecom or broadcast towers

- 🏫 Island schools or clinics

These sites benefit from fuel savings, lower O&M costs, and more stable power.

System Architecture: Key Components

A basic small-scale diesel-battery hybrid system includes:

- Diesel generator

Existing or newly specified, ideally capable of remote start/stop. - Hybrid inverter/charger

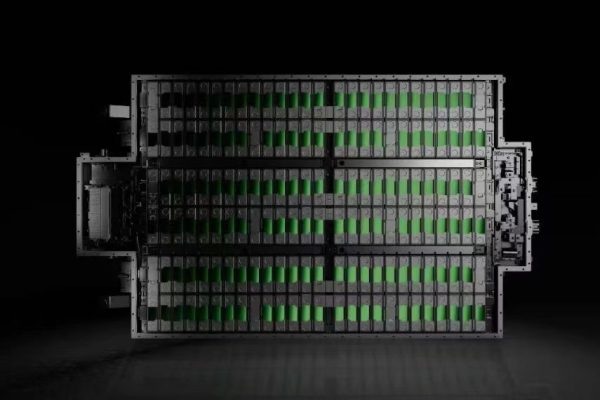

Manages power flow between genset, battery, and load. Key for synchronization. - Battery bank

Typically LFP lithium modules in the 10–100kWh range. Modular or cabinet format. - PV system (optional)

Further reduces diesel use by charging batteries in the day. - Control/EMS

Governs when to charge/discharge battery, start genset, or shed loads.

🖼️ Example layout:

Diesel → Inverter/Charger → Battery → Load

(optional PV → inverter → battery)

How the System Works in Practice

The control logic typically follows this workflow:

- Daytime (if solar present):

PV charges battery and powers load. Diesel stays off. - Evening:

Battery discharges to serve evening loads. - Night or high demand:

If battery SoC drops or load spikes, diesel starts. Inverter charges battery and powers load. - Silent hours:

Diesel off. Battery alone supports low overnight load.

This cycle minimizes diesel runtime, especially during periods of low or variable demand.

Sizing a Small Hybrid System

Proper sizing depends on load profile, runtime requirements, and budget.

| Component | Sizing Principle |

|---|---|

| Battery | Cover 6–12 hours of load (night or genset-off periods) |

| Inverter | Match peak AC load + surge margin (e.g., 1.5× motor loads) |

| Diesel | Sized for worst-case total load, but optimized to run less |

| PV (optional) | Enough to offset daily kWh demand + charge battery |

📌 Example:

- Load: 5kW average, 8kW peak

- Battery: 30kWh (for 6 hours autonomy)

- Inverter: 10kW hybrid

- Diesel: 10–15kVA

- PV: 5–8kW (optional)

Key Benefits for Small Sites

✅ Fuel savings: 40–70% depending on site and PV

✅ Lower genset maintenance: Fewer cycles, cleaner running

✅ Longer generator life

✅ Lower noise during battery-only hours

✅ Improved power quality: Less fluctuation

✅ Remote monitoring: Easy to track SoC, fuel, errors

Deployment Tips for Success

- Use compatible gensets

Ensure genset supports auto-start, remote control, and proper grounding. - Choose inverters designed for hybrid use

Not all solar inverters can interface well with gensets. Choose models with AC coupling or genset input logic. - Design for surge loads

Battery + inverter must handle motor or compressor startup. - Thermal considerations

Batteries and inverters must be installed in ventilated enclosures if diesel is nearby. - Plan SoC reserves

Keep a buffer in battery to reduce deep cycles and allow genset-free recovery.

Common Mistakes to Avoid

- ❌ Oversized gensets that run lightly: Low efficiency, high fuel waste

- ❌ Undersized batteries: System still relies too much on diesel

- ❌ Lack of EMS coordination: No clear start/stop logic

- ❌ Ignoring cooling: Batteries can overheat if near engine exhaust

- ❌ Incompatible inverter-genset pairing: Causes instability, poor sync

Case Snapshot: Remote Farm, 10kVA Genset + 30kWh Battery

Location: Southern Africa

Use case: Water pumps, cold storage, small housing

Original setup: Diesel genset runs 18 hours/day

New hybrid system:

- Hybrid inverter: 10kW

- Battery: 30kWh LFP cabinet

- PV: 6kW

- Diesel runtime: Cut to 6 hours/day

- Fuel savings: ~60%

- Noise complaints: Gone

Selling Hybrid as a Long-Term Investment

When discussing diesel-battery hybrids with your client:

- Frame it as cost-saving, not just “eco-friendly”

- Show ROI over 2–3 years based on fuel offset

- Emphasize reliability + flexibility, not just specs

- Offer expandable options — start with 15kWh battery, add more later

- Help compare fuel + maintenance costs vs. battery capex

For installers and distributors, hybrid systems also mean repeat business for O&M, battery replacements, and system upgrades.

Conclusion: A Smarter Off-Grid Future

Small hybrid diesel-battery systems are no longer niche or experimental. With the right sizing and control, even a modest system can:

- Cut fuel usage by half

- Improve power quality

- Extend generator life

- Enable future solar integration

- Offer quiet, clean nights for off-grid clients

Whether it’s for a rural homestead, island resort, or mobile base camp, these hybrid setups offer real savings and reliable energy — without requiring a full solar buildout.