When designing or sourcing an energy system, most of the focus goes to battery capacity, inverter output, and price. Yet there’s one crucial factor that determines whether your inverter performs well for years or fails early in harsh conditions: cooling.

Cooling systems may seem secondary, but they directly impact inverter lifespan, energy efficiency, and maintenance needs—especially in hot or dusty environments. For installers and buyers handling small to medium-sized PV+ESS systems (3kW–50kW), selecting the right cooling method is not optional. It’s a strategic choice.

This guide compares the three dominant inverter cooling technologies—passive, fan-based, and liquid cooling—and explains when each is most appropriate for your project.

1. Why Cooling Matters in Inverter Design

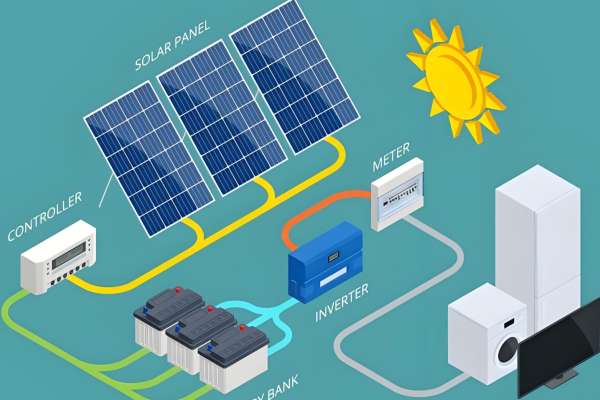

Inverters convert DC power from solar panels or batteries into AC power for household or grid use. This process generates heat, especially when the inverter runs at high power or under continuous load.

If this heat isn’t dissipated properly:

- Efficiency drops due to thermal derating

- Component aging accelerates

- Unexpected shutdowns or fire risks may occur

- Warranty may be void if thermal thresholds are violated

In tropical, desert, or poorly ventilated environments, thermal performance becomes a mission-critical design factor, not a secondary concern.

2. Three Main Cooling Strategies in Inverters

A. Passive Cooling (Natural Convection)

- How it works: Uses heatsinks and metal casing to dissipate heat naturally without moving parts.

- Key features:

- No fan = silent operation

- No airflow required = less dust intrusion

- Long service life (no mechanical wear)

Best for:

- Small hybrid inverters (<5kW)

- Indoor or shaded environments

- Regions with moderate ambient temperatures

Limitations:

- Limited heat dissipation

- Derates quickly in high ambient temperatures (>40°C)

- Larger size needed to increase surface area

B. Fan-Based Cooling (Forced Air)

- How it works: Built-in fans push air across heat sinks to increase thermal transfer.

- Key features:

- Compact designs with efficient cooling

- Common in 5kW–30kW residential and C&I inverters

- Better temperature control than passive cooling

Best for:

- Rooftop installations in hot, dusty regions

- Projects needing cost-effective solutions

- Installations with moderate maintenance access

Limitations:

- Fans attract dust, requiring filter cleaning

- Fans wear out—often the first failure point

- Higher noise levels (~30–50 dB)

Tip: Ask your supplier about fan MTBF (mean time between failure), and whether fan modules are field-replaceable.

C. Liquid Cooling

- How it works: Circulates coolant through thermal blocks to absorb heat, then expels it via radiator or heat exchanger.

- Key features:

- Superior temperature control under extreme conditions

- Used in data centers, EVs, and large ESS platforms

- Quiet and compact for the power it handles

Best for:

- High-density inverter rooms or containerized ESS

- Projects >30kW in desert, mining, or telecom settings

- Where uptime and thermal safety are mission-critical

Limitations:

- Higher cost and complexity

- Risk of leaks and pump failure

- Rarely offered in small-scale (3–15kW) inverters

3. Real-World Applications by Cooling Type

| Project Type | Region | Recommended Cooling | Why |

|---|---|---|---|

| Rural home < 5kW | Southeast Asia | Passive cooling | Quiet, low maintenance |

| Rooftop factory, 10–30kW | Middle East | Fan-based cooling | Efficient in hot dusty air |

| Coastal telecom base station | East Africa | Fan-based + corrosion proof | Compact with active cooling |

| Containerized backup 50kW | Island Resort | Liquid cooling | Space-constrained + quiet |

Environmental derating curves matter. If ambient temperatures regularly exceed 35°C, passive cooling may limit performance unless oversized. Fan-based inverters offer a good balance, but you must plan for cleaning and replacements. Liquid cooling, though ideal thermally, only makes sense at scale.

4. What Installers and Distributors Should Ask

Before purchasing or specifying an inverter cooling type, ask:

- What is the cooling method used?

Confirm if it’s fully passive, forced air, or hybrid. - Does the system include temperature protection logic?

Thermal derating should be automatic and gradual—not abrupt shutdowns. - Can the fan module be easily replaced in the field?

Some fan-based systems are modular; others are sealed. - What is the rated ambient operating range?

Look for specs like “-25°C to +60°C” and check if derating starts at 40°C. - What certifications are related to thermal performance?

UL, IEC, or CE may include temperature testing, but ask for specifics. - Is the cooling system covered under warranty?

Many warranties exclude consumables like fans—read carefully. - Any remote temperature monitoring available?

Especially useful for off-grid or container installations.

5. Cooling vs. Inverter Failure Modes

In the field, many inverter “failures” are thermal management issues in disguise:

- System shuts off at noon → thermal derating due to poor ventilation

- Output dips under full load → fans clogged or heat sinks coated in dust

- Fan runs constantly even at night → failed thermal sensor or faulty firmware

A well-selected and properly maintained cooling strategy eliminates over 40% of avoidable inverter performance issues in small installations.

6. Recommendations for Small Project Buyers

| Scenario | Suggested Cooling Type |

|---|---|

| < 5kW, rural home | Passive |

| 5–15kW, hybrid rooftop, warm climate | Fan-based, IP65 if outdoors |

| 20–50kW, indoor microgrid | Fan-based with thermal alarms |

| Container backup in remote areas | Liquid cooling (if budget allows) |

If you’re buying from a manufacturer or trader, ask for temperature performance charts, not just a brochure. In hot climates, a “cheap” inverter with poor cooling can become more expensive over time due to early failure, downtime, or battery stress.

Cooling is Not Just an Engineering Detail

Whether you’re an installer in Africa, a trader in Southeast Asia, or an EPC looking to scale rooftop systems, cooling matters. It’s not just about performance—it’s about protecting your customer’s investment and your reputation.

A well-cooled inverter runs longer, more efficiently, and with fewer surprises. Match the cooling strategy to the project environment—not just the price—and your system will be more resilient for years to come.