Introduction: Portable, Scalable Power for Dynamic Needs

In today’s rapidly changing environments — from remote construction sites to temporary event venues, from disaster relief zones to agricultural field operations — the need for mobile and modular power solutions is growing. These applications often lack fixed infrastructure and require energy systems that are easy to transport, set up, and expand.

Modular battery systems offer a flexible path forward. When paired with a suitable inverter and optional solar input, they become a reliable, clean, and user-friendly mobile power source.

In this guide, we’ll show you how to build a mobile power supply using modular batteries, including key technical and design considerations that can help you avoid over-engineering while ensuring safety and scalability.

1. What Is a Modular Battery System?

A modular battery system is one where:

- Batteries come in stackable or rackable units, often in 2kWh to 10kWh sizes.

- Modules are designed to be plug-and-play — easy to connect in series or parallel.

- You can scale up total capacity based on runtime requirements or load expansion.

These systems are ideal for applications where:

- Load profiles change regularly.

- Space and weight are constrained.

- Portability is critical.

2. Common Use Cases for Mobile ESS

A. Events & Exhibitions

Outdoor concerts, booths, and expos need silent, clean energy.

B. Disaster Relief

Mobile batteries are ideal for emergency lighting, charging stations, or medical equipment.

C. Construction & Mining Sites

Where power access is limited or generators are too loud or costly.

D. Off-grid Field Work

From agriculture to research, mobile units support essential electronics and tools.

3. System Architecture Overview

A typical mobile power system consists of:

| Component | Function |

|---|---|

| Modular Battery Pack | Provides scalable energy storage |

| Hybrid or Off-grid Inverter | Converts battery DC to AC; manages solar/grid/generator input |

| AC/DC Output Panel | Distributes power to devices, tools, or appliances |

| Charging Input (Optional) | Accepts PV, grid, or generator input |

| Transport Container or Frame | Makes the system mobile and protected |

For true mobility, all components should fit into a single rack, cabinet, or wheeled case.

4. Battery Configuration Tips

4.1. Voltage Compatibility

- Match battery voltage to inverter specs (typically 48V for small mobile units).

- Choose battery modules that support parallel connection for capacity scaling.

4.2. Chemistry Choice

- LFP (LiFePO₄) is strongly recommended for:

- Safety (especially in transport)

- Long cycle life

- Thermal stability

4.3. Size and Portability

- Aim for battery modules under 30kg for single-person handling.

- Use handles, brackets, or trolley carts for safer movement.

5. Inverter Selection Criteria

- Must be able to operate in off-grid or standalone mode.

- Consider inverter output power based on tools or appliances you’ll run:

- 3kW: laptops, LED lighting, small tools

- 5kW–10kW: refrigerators, fans, large equipment

- Look for fast switching time (under 20ms) if powering sensitive devices.

- Choose an inverter that can charge from both PV and AC if needed.

6. Charging Flexibility

To ensure the system is versatile in the field:

- Add a solar input (MPPT) for daytime recharging.

- Include a grid input or portable generator socket for nighttime or rainy-day backup.

- Optional: integrate a charge controller or use inverter’s built-in charging.

7. Mounting and Mobility

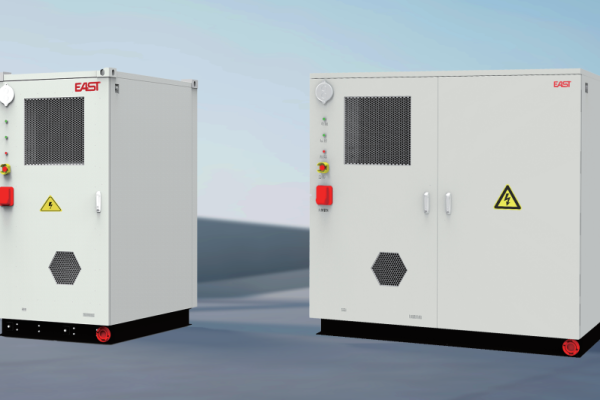

Depending on the application, choose the right form factor:

- Flight case or trolley rack: ideal for touring events or workshops.

- Wheeled cabinet: suits semi-permanent field installations.

- Containerized mobile room: for larger energy demand (20kWh–100kWh).

Don’t forget:

- Add shock absorbers or padding for transport.

- Include ventilation fans or passive cooling if operating in hot climates.

8. Monitoring and Safety

Even a mobile system needs visibility and protection:

- Use a Battery Management System (BMS) with LCD or Bluetooth app.

- Add an overload breaker, fuses, and EMI filters.

- Monitor SOC (State of Charge) and runtime estimates for field planning.

9. Benefits Over Traditional Generators

| Feature | Modular ESS | Diesel Generator |

|---|---|---|

| Noise | Silent | Loud |

| Emissions | None | CO₂ and particulate |

| Fuel Handling | Not required | Needs refueling |

| Startup Time | Instant | Delayed |

| Scalability | Easy to add more batteries | Limited or fixed output |

10. Sourcing as a Trade Partner

If you’re helping clients source these systems:

- Ask what daily usage they expect (kWh).

- Check if they need solar recharge capability.

- Clarify if mobility is permanent or occasional — this affects form factor.

- Work with suppliers that offer stackable batteries, integrated hybrid inverters, and pre-wired kits.

Your value lies in helping clients balance:

- Portability vs. capacity

- Budget vs. durability

- Scalability vs. simplicity

Conclusion

Building a mobile power supply system using modular batteries is more than stacking hardware — it’s about enabling energy independence in places where the grid can’t go. Whether you’re supplying an outdoor festival, a rural health camp, or a mobile workshop, the right combination of batteries, inverter, and layout makes all the difference.

Choose proven lithium solutions, ensure the inverter is ready for field deployment, and design with plug-and-play expansion in mind. In doing so, you empower users to take energy anywhere — safely and reliably.