How Intelligent Control Systems Unlock the Full Value of Distributed Energy

As microgrids become a growing solution for energy reliability, decarbonization, and cost savings—especially in remote, industrial, or underserved areas—the integration of battery energy storage systems (BESS) introduces new opportunities and challenges for energy management.

Unlike traditional grids, microgrids require real-time control, multi-source coordination, and dynamic load balancing. In this article, we break down the key energy management strategies used in microgrids with battery storage, helping foreign trade professionals understand how different control logics influence system design, component selection, and long-term performance.

1. What Is a Microgrid?

A microgrid is a localized energy system capable of operating independently or in conjunction with the main utility grid. It typically includes:

- Distributed generation (e.g., solar PV, wind turbines, diesel gensets)

- Battery energy storage systems (BESS)

- Local loads (residential, commercial, or industrial)

- A central controller or EMS (Energy Management System)

💡 In off-grid or islanded mode, the microgrid must independently balance supply and demand 24/7.

2. Why Energy Management Is Crucial

Unlike standalone PV or backup systems, microgrids require complex, intelligent energy coordination. Without a proper energy management strategy:

- Batteries may degrade quickly due to improper cycling

- Loads might suffer outages during supply imbalance

- Diesel generators could run inefficiently

- PV output may be curtailed or underused

The EMS (Energy Management System) is the brain of the microgrid, executing real-time strategies to optimize energy flows based on system priorities, forecasts, and conditions.

3. Key Components of a Microgrid with Storage

Before exploring strategies, let’s clarify the main assets involved:

| Component | Role |

|---|---|

| PV Array | Renewable daytime generation |

| Diesel Generator | Backup or baseload support |

| Battery System (BESS) | Energy shifting, backup, and smoothing |

| Loads | Homes, offices, machinery, lighting, etc. |

| EMS / Controller | Real-time energy control and system logic |

| Smart Meters | Measure consumption and generation |

| Switchgear & ATS | Manage grid/microgrid transition |

4. Common Energy Management Objectives

A smart EMS optimizes multiple variables. The exact strategy depends on project goals, such as:

| Objective | Description |

|---|---|

| Maximize Renewable Usage | Prioritize solar and wind over fossil fuels |

| Peak Load Management | Avoid generator overload or demand surges |

| Fuel Cost Optimization | Minimize genset runtime to save diesel fuel |

| Battery Health Preservation | Avoid over-cycling, deep discharge, or overheating |

| Load Prioritization | Ensure critical loads always have power |

| Grid Synchronization | Support smooth transitions between on-grid and islanded |

5. Core Energy Management Strategies

A. Solar Priority with Battery Support

Use Case: Off-grid microgrids with stable daytime load and solar PV

Logic:

- Use solar to serve loads directly

- Charge battery with excess PV

- Discharge battery during evening

- Use genset only if battery SoC < threshold

Benefits:

- Maximum solar utilization

- Reduced generator runtime

- High battery cycling

Design Tip: Use LFP batteries with high DoD and 6000+ cycle life.

B. Load Shaving + Fuel Optimization

Use Case: Remote industrial sites with limited genset capacity

Logic:

- Battery supports during peak loads (discharge)

- Genset runs at optimal, steady load range

- Battery recharges during off-peak times

Benefits:

- Avoid genset overloads

- Minimize fuel usage

- Balance loads smoothly

💡 Related: Choosing PCS for Industrial Projects

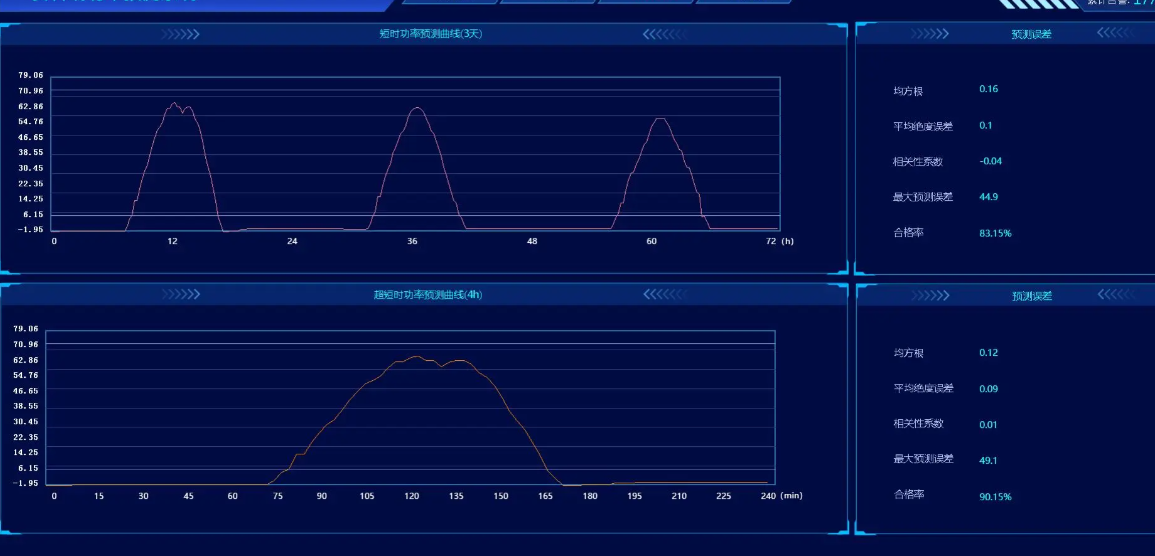

C. Forecast-Based Dispatch

Use Case: Microgrids with weather variability and time-based tariffs

Logic:

- EMS uses solar production forecasts and load prediction

- Adjusts charging/discharging to align with expected availability

- Prioritizes storage for cloudy days or anticipated spikes

Benefits:

- Improved reliability

- Prevents unexpected genset use

- Efficient solar capture

Challenge: Requires advanced EMS with machine learning or cloud data integration

D. Grid-Connected with Islanding Capability

Use Case: Commercial sites with unreliable grid

Logic:

- Operate in grid-connected mode under normal conditions

- Battery handles peak shaving or time-of-use arbitrage

- Automatically switch to off-grid mode during outages

- EMS dynamically adapts load/generation during transition

Benefits:

- Grid cost savings

- Seamless backup power

- System flexibility

💡 Tip: Inverter and PCS must support seamless transfer & black start.

E. Load Prioritization & Shedding

Use Case: Critical facilities (hospitals, telecom, cold storage)

Logic:

- Define load tiers (Critical / Essential / Non-Essential)

- In outage or limited energy scenarios, shed non-essential loads

- Maintain power to Tier 1 loads at all costs

Benefits:

- Guarantees energy availability for mission-critical functions

- Extends usable battery time during emergencies

6. Role of EMS and Control Algorithms

Modern microgrids rely on programmable EMS platforms or pre-configured hybrid controllers. Key functions include:

- SoC and battery thermal monitoring

- Source dispatch control (PV, genset, BESS)

- Real-time optimization

- Grid synchronization

- Fault detection and auto-recovery

- Communication with inverters, meters, and BMS

Popular communication protocols: MODBUS, CAN, RS485, Ethernet

💡 Related: How to Select an EMS for PV+Storage Systems

7. Battery Storage Considerations

Sizing

Depends on:

- Load profile

- PV capacity

- Outage frequency (if backup needed)

- Desired autonomy (e.g., 4 hours, 1 day)

👉 See: How to Size a Battery System for Small Commercial Projects

Performance

- LFP batteries preferred for thermal safety and long life

- ≥6000 cycles recommended

- High roundtrip efficiency (≥90%)

- Fast charge/discharge support (0.5C–1C) for power-intensive use

8. Example Microgrid Scenarios

📍 Off-Grid Resort

- Solar PV: 80 kW

- Battery: 400 kWh

- Diesel Genset: 100 kW

- EMS: PV priority, genset backup

- Goal: >90% solar usage

Outcome: Fuel cost savings > 70%, stable energy during tourist season

🏭 Industrial Site with Load Spikes

- PV: 150 kW

- Battery: 250 kWh, 1C

- Grid-connected, weak grid

- EMS: Peak shaving, islanding capable

Outcome: Reduced grid demand penalties, blackout resilience

9. Procurement Tips for Foreign Trade Partners

When sourcing components for microgrid projects:

- Clarify EMS roles: Is it inverter-integrated or external PLC-based?

- Check communication compatibility: Between inverter, BMS, genset, and EMS

- Validate black-start capability: For off-grid scenarios

- Provide battery specs with EMS tuning options

- Offer system-level BOM support: Not just individual parts

Your value as a foreign trade partner lies in connecting the right hardware with appropriate control logic.

10. Final Thoughts: Strategy First, Hardware Second

Energy management strategies should guide how you select batteries, hybrid inverters, controllers, and even cables. Understanding the microgrid use case enables:

- Better system performance

- Lower operating costs

- Longer asset lifespan

- Stronger client trust

By mastering EMS strategies, you move from “seller” to solution provider—a key differentiator in the emerging microgrid economy.

If you’re supporting microgrid developers, EPCs, or distributors, we can help you source complete systems—from BESS, PCS, EMS to installation kits—backed by technical consultation and global delivery support.