Tips for First Installations That Build Trust and Market Confidence

Why Start with a Pilot?

If you’re a solar distributor or energy entrepreneur looking to expand into battery storage, your first installation matters more than your first shipment. A well-executed pilot project does three things:

- Builds trust with your local market

- Creates a physical reference for future clients

- Gives your team hands-on learning before scaling

Whether you’re working with 5kWh systems for homes or 50kWh units for small businesses, a strategic first deployment helps you position yourself not just as a product seller — but as a capable technical partner.

This guide outlines how to build an effective pilot storage project that sets the tone for your growth.

Step 1: Define Your Pilot Objective

Before choosing brands or wiring layouts, define what this pilot needs to prove. Your goal could be:

- Showing backup power in grid outage areas

- Demonstrating peak shaving in small industrial settings

- Building a local testbed for future system rollouts

- Training your installer partners or internal team

- Providing a walk-in demo site for customers

📌 Tip: Don’t try to do everything. One clear purpose is enough for a pilot.

Step 2: Choose the Right Pilot Site

For your first system, site conditions are just as important as specs. The ideal pilot site should be:

- Easily accessible (not too remote or high-risk)

- Representative of your target market (e.g., home, shop, farm)

- Owned or operated by a trusted partner or early adopter

- Willing to allow regular monitoring and visits

- Flexible on design iterations if needed

If you’re a distributor, installing a system in your own office or warehouse can double as a sales showroom and training hub.

Step 3: Pick Simple, Reliable Components

In pilot systems, reliability and ease-of-use are more valuable than advanced features. Choose components that are:

- Pre-integrated or all-in-one, to reduce commissioning errors

- Modular and scalable, so future upgrades are easy

- From brands with technical support and clear documentation

- Known to work together (e.g., inverter and battery compatibility is tested)

Example setups for small pilot projects:

| Site Type | Size | Suggested Setup |

|---|---|---|

| Rural Home | 5kW / 10kWh | Hybrid inverter + LFP battery + AC loads |

| Office Building | 10kW / 20kWh | AC-coupled system with EMS monitoring |

| Farm or Factory | 15kW / 30kWh | 2-string PV + hybrid + high-voltage rack |

📌 Tip: Choose lithium iron phosphate (LFP) batteries if safety and cycle life are priorities.

Step 4: Keep the Layout Simple

For a first system, avoid overcomplicating the structure. A clear, modular layout:

- Reduces installation time

- Makes component behavior easier to troubleshoot

- Helps clients visually understand the solution

Examples of clean pilot layouts:

- Wall-mounted hybrid inverter + floor battery cabinet

- Rack-mount 48V system with combiner + inverter cabinet

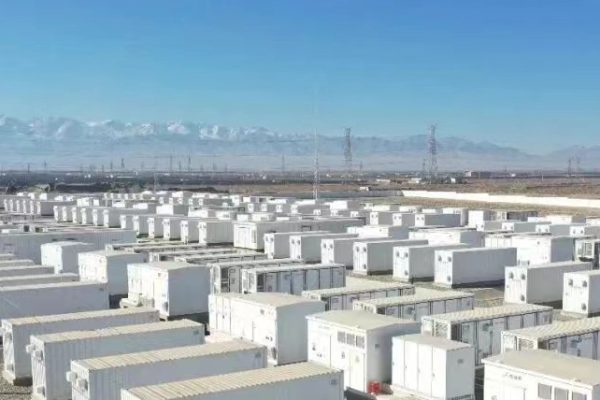

- Containerized setup with transparent labeling for demo use

Include clear signage and visual meters/screens so visitors can see what’s happening.

Step 5: Involve the Client in the Process

A pilot project is also an educational tool. Invite the client to:

- Review system sizing logic

- Learn basic monitoring/dashboard usage

- See how performance evolves over days or weeks

Your goal is not just a working system — it’s a client who becomes your advocate. Ask for:

- Photos and testimonials

- Data access for case studies

- Permission to bring new prospects to visit

Step 6: Prepare for Support & Data Collection

Plan in advance how you will monitor performance and support the site:

- Use systems with built-in Wi-Fi or RS485-to-cloud data upload

- Assign one technician to check logs for the first 2 weeks

- Track battery SoC, charge/discharge events, PV generation, and grid interaction

- Record how the system responds during outages or peak hours

This data becomes critical for:

- Troubleshooting

- Marketing future projects

- Optimizing your next installation

Common Pitfalls in First Projects (and How to Avoid Them)

| Pitfall | Solution |

|---|---|

| Mismatched inverter and battery comms | Pre-confirm protocol: CAN, RS485, or Modbus compatibility |

| Oversizing PV relative to inverter | Check hybrid inverter PV input limits |

| Underestimating surge load needs | Include 20–30% margin in inverter sizing |

| Poor ventilation in battery room | Follow cabinet airflow and thermal spacing guidelines |

| No backup circuit isolation | Install critical load panel or dedicated backup switch |

Step 7: Use the Pilot as a Growth Engine

Once your pilot system is running smoothly:

- Invite new customers to visit

- Share monitored performance graphs online

- Turn lessons learned into sales materials

- Host a short workshop for local installers

- Create a short video walkthrough in your local language

📌 Remember: This project is not just about today’s ROI — it’s your technical credibility on display.

What Clients See in a Pilot

To non-technical buyers, a pilot project is not just about specs. It helps them answer:

- “Will this work for me?”

- “Can I trust this distributor to support it?”

- “Does it look neat and safe?”

- “Is this the brand I want to associate with?”

By making your first system visible, understandable, and well-supported, you shorten the sales cycle for the next 10 systems.

Conclusion: Don’t Just Sell — Demonstrate

As a distributor, your edge isn’t just access to products. It’s your ability to connect product to application, and prove it with a real-world, working system.

A well-designed pilot:

- Builds confidence for your team and clients

- Creates marketing momentum

- Establishes your brand in the energy storage space

- Helps you gather valuable feedback before large-scale rollout

Start simple. Document everything. Support it well. Let the pilot speak for you.