Industrial parks face growing energy challenges: rising peak demand charges, variable renewable generation, and the need for uninterrupted operations. Integrating modular energy storage systems (ESS) with a centralized Energy Management System (EMS) provides an effective solution for load balancing, peak shaving, and operational flexibility.

This article outlines a replicable integration framework, shares real-world deployment experiences, and highlights key technical insights for industrial park operators and integrators seeking reliable, modular, and controllable storage solutions.

1. Why Modular Storage with EMS Matters

Industrial parks often consist of multiple facilities with varying load profiles. Challenges include:

- High peak demand charges due to synchronized energy use

- Intermittent renewable generation, such as PV systems

- Operational continuity requirements, especially for critical processes

- Scalability needs as facilities expand

Modular ESS integrated with EMS addresses these by:

- Coordinating distributed storage units across the park

- Optimizing energy flows between PV, grid, and storage

- Enabling predictive load management and peak shaving

- Simplifying maintenance through modular replacement

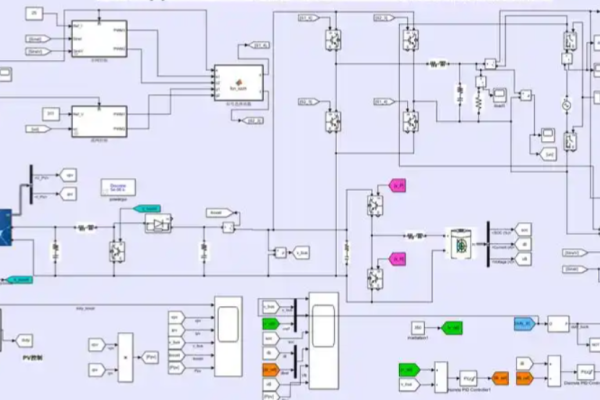

2. Core Integration Architecture

a) Modular ESS Design

Key characteristics for industrial park integration:

- Scalable capacity: Each module can operate independently or in parallel.

- Hot-swap capability: Replace individual modules without disrupting the park.

- Redundant monitoring: Each module with local BMS reporting to EMS.

Technical Insight:

A modular layout with 5–10 kWh units allows incremental scaling, reducing upfront CAPEX and enabling phased deployment.

b) Energy Management System (EMS)

EMS is the central control layer, coordinating all energy assets:

- Load Forecasting: Anticipates park energy needs using historical data and real-time measurements.

- Peak Shaving Algorithms: Discharges batteries during high-demand periods to reduce grid charges.

- Renewable Integration: Stores excess PV energy and dispatches it when needed.

- Redundancy and Failover: Ensures continuous operation if a module or communication link fails.

Architecture Overview:

- Sensors & Data Acquisition: Measure load, PV output, battery SOC, and environmental conditions.

- Module-Level BMS: Communicates health and operational data to EMS.

- Central EMS: Executes optimization algorithms and dispatch commands.

- Grid Interface: Manages import/export and ensures compliance with grid codes.

3. Integration Strategies for Industrial Parks

a) Distributed vs Centralized Storage

- Distributed: Modules installed near high-consumption units reduce local peak demand but increase complexity.

- Centralized: Storage consolidated in one area simplifies control and maintenance but may require larger capacity modules.

Recommendation:

Hybrid approach — central storage for base load management, distributed modules for critical or high-demand zones.

b) Load Shifting and Peak Shaving

- Peak shaving: Discharge during peak tariff periods.

- Load leveling: Store off-peak energy to reduce evening or midday spikes.

- Demand charge reduction: Real-time EMS algorithms optimize battery dispatch to minimize grid peak power.

c) Renewable Energy Integration

- Store excess PV energy during mid-day for evening or night use.

- EMS predicts PV output based on weather and historical data.

- Modular ESS allows incremental addition of storage capacity as PV generation increases.

4. Real-World Case Study: Industrial Park Peak Shaving

Project Overview:

- Location: Southeast Asia

- Park Size: 50,000 m², 12 factories

- Load Profile: Peak demand 2.5 MW

- Storage: 500 kWh modular LiFePO₄ (50 × 10 kWh modules)

- EMS: Centralized with predictive peak shaving and PV coordination

Implementation Highlights:

- Modules connected to local BMS, reporting SOC, temperature, and fault status to EMS.

- EMS used predictive algorithms to discharge storage during tariff peaks (12:00–14:00 and 18:00–20:00).

- Distributed modules installed near high-demand factories to reduce localized peaks.

Results:

- Peak demand reduced by 18% on average

- Energy cost savings: 12% annually

- Storage operated at 90% uptime

- Modular replacement allowed one module swap without affecting overall park operations

Lesson Learned:

Modular design with centralized EMS enabled predictable peak shaving while maintaining flexibility for expansion and maintenance.

5. Key Technical Insights

- Predictive Load Control: EMS algorithms leveraging historical patterns reduce unnecessary cycling and extend battery life.

- Modular Redundancy: Hot-swap modules ensure uptime even during maintenance or faults.

- Thermal Management Integration: Module-level cooling improves reliability under high load periods.

- Communication Reliability: Use dual-channel communication (wired + wireless) to avoid single points of failure.

- Scalability: Modular architecture allows gradual capacity expansion in line with industrial park growth.

6. Implementation Best Practices

| Aspect | Recommendation |

|---|---|

| Modular ESS | Hot-swap design, scalable 5–20 kWh units |

| EMS | Predictive algorithms for peak shaving and load leveling |

| Communication | Redundant channels, robust data acquisition |

| Thermal & Safety | Integrated module-level cooling, BMS-based protection |

| Maintenance | Scheduled predictive checks, remote monitoring |

7. Future Trends

- AI-Enhanced EMS: Advanced forecasting and dynamic optimization of storage dispatch.

- Integration with Smart Grid: Automated demand response participation for industrial parks.

- Hybrid Energy Systems: Coordination of ESS with on-site PV, CHP, and EV chargers.

- Digital Twin Modeling: Real-time simulation to improve operational planning and predictive maintenance.

Integrating modular energy storage with EMS transforms industrial parks into flexible, cost-efficient, and reliable energy ecosystems. By combining predictive control, modular redundancy, and renewable coordination, operators can reduce peak demand, optimize energy costs, and maintain continuous operations — all while allowing phased expansion and simplified maintenance.

Modular ESS + EMS is no longer an optional upgrade; it is a strategic enabler for modern industrial parks aiming for operational efficiency and resilience.