As more commercial and industrial facilities move toward cleaner and smarter energy usage, integrating solar photovoltaic (PV) systems with energy storage (ESS) has become a winning strategy. However, upgrading an existing building, factory, or grid connection with new PV-storage equipment is not always straightforward.

This article explains the top engineering, safety, and operational challenges faced when adding PV-storage systems to existing infrastructure — and how to solve them.

1. Electrical Capacity Limitations

Many existing buildings were originally designed without rooftop solar or battery loads.

Common issues include:

- Undersized main switchboards

- Limited breaker space

- Low short-circuit current tolerance

- Restricted transformer capacity

⚠️ If PV injection exceeds the building’s designed load, overcurrent and voltage rise may occur.

Recommendations:

✅ Conduct a pre-installation load analysis

✅ Add distribution board upgrades if required

✅ Consider export limiting with a smart EMS

2. Load Profile Mismatch

PV generation is highest during the day

But industrial loads may peak:

- Early morning at startup

- Evening or night shifts

- During high-power equipment cycles

Without storage, excess PV is wasted.

Solution:

- Add battery capacity sized to load curve

- Implement peak shaving and load shifting strategies

- Use EMS with predictive optimization based on demand and weather

3. Three-Phase vs. Single-Phase Incompatibility

Older buildings — especially residential or small commercial — may only have single-phase electrical service.

Challenges:

- Many hybrid inverters require three-phase

- Load imbalance may cause voltage distortion

Possible upgrades:

- Convert to three-phase service (utility approval required)

- Deploy multiple single-phase inverters across phases

- Add phase balancing in EMS

4. Roof and Structure Constraints

PV systems require strong mounting structures.

Older buildings may have:

- Weak roofing materials

- Water leakage concerns

- Limited surface area or shading from equipment

What to do:

- Conduct roof integrity inspection

- Use Ballasted or non-penetrative mounting solutions

- Consider carport or ground-mounted PV if rooftop is not suitable

- Optimize orientation with high-efficiency modules

5. Safety Compliance and Codes

Upgrading infrastructure triggers modern safety requirements:

- Rapid shutdown equipment for rooftop PV (in some regions)

- ESS fire compliance such as UL9540A / NFPA 855

- Arc-fault protection for PV strings

- Proper isolation and disconnects for emergency response

✅ Compliance ensures approval from regulators and insurers.

6. Communication and Control System Complexity

Legacy systems often lack digital controls, while ESS requires robust communication:

- PCS ↔ BMS ↔ EMS interoperability

- Protocols: RS485, CAN, Modbus TCP/IP

- Cybersecurity protection for networked devices

Fix:

- Select systems with open protocols

- Ensure manufacturer-verified compatibility

- Implement centralized monitoring software

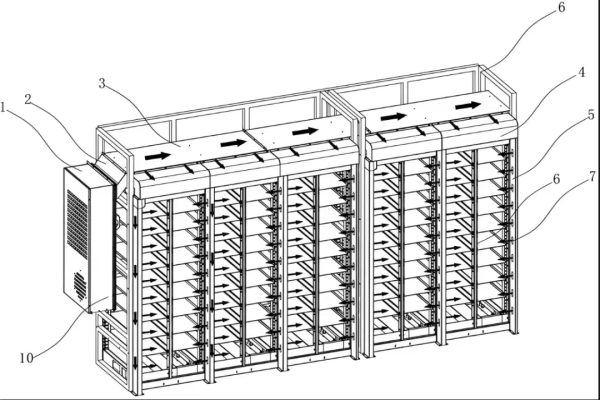

7. Space Constraints for Batteries and Inverters

Indoor rooms may lack ventilation or safety clearance, leading to:

- Heat accumulation

- Difficult maintenance access

- Higher installation costs

Alternatives:

- Outdoor IP54-rated inverter enclosures

- All-in-one ESS cabinets with fire-rated design

- Containerized ESS for higher capacity projects

8. Grid Export Limitations

Utility grid may restrict how much solar can be exported:

- Avoid feeding power that destabilizes local grid

- May require zero-export hybrid mode

- Export compensation may be low or unavailable

Recommended approach:

- Size PV to match self-consumption

- Use ESS to maximize on-site usage

- Request grid interconnection study early in project planning

9. Energy Data Uncertainty

Facilities without smart meters often lack accurate:

- Consumption patterns

- Load peak duration

- Seasonal variation

This leads to wrong system sizing.

✅ Solution: Install temporary data loggers

Collect 30–90 days of data before final design

10. Regulatory Approval Delays

Government and utility review timelines can slow deployment:

- Fire permits for battery rooms

- Structural approval for rooftop PV

- Grid interconnection agreement

Tip: Work with suppliers who can provide:**

✔ Complete documentation package

✔ Standardized system certification

✔ Compliance drawings and calculations

11. Recommended Integration Workflow

| Step | Goal | Tools |

|---|---|---|

| Load & infrastructure audit | Understand system limits | Data loggers, utility bills |

| System design & simulation | Optimize PV + ESS mix | EMS modeling tools |

| Structural & safety review | Ensure safe installation | UL9540A / NFPA 855 standards |

| Utility permissions | Export or zero-export configuration | Interconnection documents |

| Installation & commissioning | Validate onsite performance | EMS test & acceptance |

12. Case Study — Existing Retail Store Upgrade

| Item | Before | After Upgrade |

|---|---|---|

| Load Profile | High evening consumption | Shifted with battery |

| Rooftop | HVAC shading | Re-layout + higher-efficiency PV modules |

| Electricity Bill | High peak demand cost | -35% annual savings |

| System Installed | — | 80 kW PV + 120 kWh LFP ESS + Hybrid PCS |

✅ Payback period: 3.5 years

🌱 CO₂ reduction: 62 tons/year

Integrating PV-storage into existing buildings is a smart and profitable investment, but technical challenges must be carefully addressed.

Key Takeaways:

✅ Validate infrastructure capacity before design

✅ Battery + EMS is essential to solve load mismatch

✅ Structural and safety compliance must not be overlooked

✅ Open communication and interoperability ensure future expansion

✅ Early grid approval prevents costly delays

The most successful PV-storage upgrades pair technical expertise with customized design based on real-world conditions.