In any commercial or industrial (C&I) energy storage project, the Power Conversion System (PCS) plays a central role — it’s the brain and muscle that controls energy flow between the battery, grid, and loads.

Choosing the right PCS (sometimes called a bidirectional inverter) is critical for ensuring efficiency, stability, and compatibility across multiple components such as PV systems, EMS software, and grid interconnection.

This article explains what makes a PCS “compatible,” explores major PCS configurations, and outlines how to select the best PCS for commercial energy storage systems (ESS).

1. What Is a PCS in Energy Storage Systems?

A Power Conversion System (PCS) manages the bidirectional conversion between DC power from batteries and AC power for the grid or loads.

Basic Functions:

- Convert DC → AC for discharge to loads or grid

- Convert AC → DC for charging the battery

- Manage reactive power compensation (VAR)

- Support grid stability and frequency control

- Communicate with Battery Management System (BMS) and Energy Management System (EMS)

[Grid / PV] ↔ [PCS] ↔ [Battery Rack]

↓

[Commercial Loads]

A well-chosen PCS ensures:

✅ Efficient energy transfer

✅ Smooth operation with PV and EMS

✅ Compliance with local grid standards

2. PCS vs. Inverter: What’s the Difference?

While often used interchangeably, PCS and inverter have nuanced differences:

| Aspect | PCS (Bidirectional) | Inverter (Unidirectional) |

|---|---|---|

| Direction | AC↔DC (charge & discharge) | DC→AC only |

| Use Case | Energy storage systems | PV generation |

| Control | Grid-forming & grid-following | Grid-following |

| Example | Battery-based microgrid | Solar inverter |

In short, all PCS units are inverters, but not all inverters can function as PCS.

3. Key PCS Configurations

3.1 AC-Coupled PCS

Connects to the AC bus of the facility or grid.

- Each system (PV, ESS, grid) has its own inverter.

- ESS charges/discharges through the AC connection.

Advantages:

✅ Simple integration with existing PV systems

✅ Ideal for retrofits

Disadvantages:

⚠️ Multiple energy conversions (lower efficiency)

⚠️ Slightly higher system losses

Typical Use Case:

Add-on storage for factories or commercial buildings with existing PV arrays.

3.2 DC-Coupled PCS

Connects PV arrays and battery on a shared DC bus.

- The PCS manages both solar input and battery charge/discharge.

- Fewer conversion steps, higher overall efficiency.

Advantages:

✅ 3–5% higher energy yield

✅ Compact and cost-effective

✅ Ideal for new PV + Storage projects

Disadvantages:

⚠️ Complex DC bus design

⚠️ Requires precise component matching

Typical Use Case:

Integrated hybrid systems for new commercial facilities.

3.3 Hybrid PCS

Combines both AC and DC coupling in one unit.

- Can connect to grid, battery, and PV simultaneously.

- Offers highest flexibility for diverse system layouts.

Advantages:

✅ Handles PV, battery, and grid power concurrently

✅ Simplifies installation and control

✅ Ideal for commercial microgrids

Disadvantages:

⚠️ Higher initial cost

⚠️ More complex firmware configuration

4. Key Technical Parameters for PCS Selection

When comparing PCS options, buyers should focus on several technical parameters that directly affect system performance.

| Parameter | Description | Recommended Range (C&I) |

|---|---|---|

| Rated Power | Maximum continuous output | 30 kW – 1000 kW |

| AC Voltage | Nominal grid connection voltage | 380V / 400V / 480V |

| DC Voltage Range | Battery voltage window | 600V – 1500V |

| Efficiency | Conversion efficiency | ≥ 97% |

| THD (Total Harmonic Distortion) | Power quality indicator | < 3% |

| Power Factor Control | Reactive power support | -0.9 to +0.9 |

| Communication | BMS/EMS protocol | MODBUS TCP, CAN, RS485 |

| Grid Standards | Regional compliance | IEC 61850, IEEE 1547, UL 1741 |

💡 Tip: When in doubt, choose PCS models certified for UL 9540 / IEC 62933 and capable of bidirectional operation.

5. Communication Compatibility

A critical (and often overlooked) factor is protocol compatibility between PCS, battery, and EMS.

Typical Communication Interfaces:

- CAN Bus: Battery communication (real-time voltage, SOC, alarms)

- RS485 / MODBUS: PCS to EMS or monitoring system

- Ethernet / TCP/IP: Remote control and cloud connection

Why Compatibility Matters:

- Ensures accurate charge/discharge control

- Prevents false alarms and communication dropouts

- Enables full remote monitoring and firmware upgrades

Example:

If your LFP battery uses MODBUS RTU, ensure your PCS can map these registers correctly — otherwise, EMS data may be inaccurate or incomplete.

6. Cooling and Installation Form Factors

PCS units for commercial ESS are usually:

- Wall-mounted (≤ 100 kW)

- Cabinet-mounted (100–500 kW)

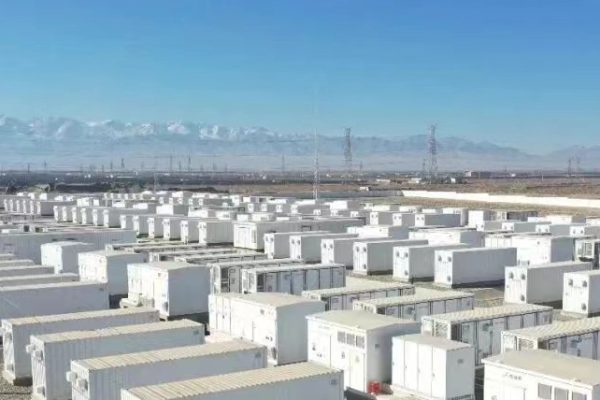

- Containerized (> 500 kW)

Cooling Methods:

- Forced Air Cooling: Compact and cost-effective for indoor systems.

- Liquid Cooling: Higher power density, better for outdoor or high-temperature environments.

⚙️ Example: A 500 kW PCS with liquid cooling can operate continuously in 45°C environments — critical for tropical or desert installations.

7. Single vs. Three-Phase PCS

| Feature | Single-Phase PCS | Three-Phase PCS |

|---|---|---|

| Power Range | < 30 kW | 30–1000 kW |

| Use Case | Residential, small office | Commercial, industrial |

| Grid Support | Limited | Full reactive power support |

| Parallel Capability | Rare | Common (up to 4–8 units) |

For C&I storage, three-phase PCS is standard, enabling:

- Load balancing

- Parallel redundancy

- Smart control with EMS

8. Typical PCS Brands and Compatibility Examples

| Brand | Country/Region | Typical Range | Known for |

|---|---|---|---|

| Sungrow | China | 50–500 kW | High efficiency, wide BMS compatibility |

| GoodWe | China | 30–250 kW | Compact hybrid solutions |

| Huawei | China | 100–1000 kW | Integrated AI-based EMS |

| Sinexcel | China | 60–500 kW | Modular PCS with strong grid performance |

| Delta / SMA | Germany / Taiwan | 50–500 kW | Proven reliability and grid compliance |

| TBEA / Kehua | China | 100–1500 kW | Industrial-grade hybrid PCS |

| Socomec / Eaton | EU / US | 100–500 kW | Safety and high protection standards |

✅ Tip for Buyers:

Always request compatibility test reports (battery–PCS protocol validation) before finalizing procurement.

9. Parallel Operation and Scalability

In commercial ESS projects, power demand often grows over time.

Choose a PCS that supports parallel operation and modular expansion.

Features to check:

- Master–slave synchronization

- Load sharing (active power and reactive power)

- Anti-islanding and fault ride-through compliance

Example:

Four 250 kW PCS units connected in parallel → total 1 MW system.

If one unit fails, others continue operating with minimal downtime.

10. Safety Features to Prioritize

Commercial ESS PCS should meet high safety standards, including:

- Anti-islanding protection

- DC insulation monitoring

- Ground fault detection

- Overvoltage and surge protection

- Emergency stop interface

- Arc-fault circuit interruption (AFCI)

Compliance with UL 9540A, NFPA 855, and IEC 62933 ensures safe and stable long-term operation.

11. Integration with EMS and Grid

The PCS must seamlessly integrate with the Energy Management System (EMS) for functions such as:

- Load management

- Peak shaving and demand response

- Frequency regulation

- Time-of-use optimization

For grid-tied commercial ESS, the PCS must also meet utility interconnection standards (e.g., IEEE 1547, GB/T 34120).

🔌 Example: In a demand charge reduction project, EMS signals the PCS to discharge during 5–9 PM peak, automatically shifting to grid-charging at midnight — all controlled through MODBUS commands.

12. Example: 500 kWh Commercial ESS

System Design:

- Battery: 500 kWh LFP rack system (768V nominal)

- PCS: 250 kW × 2 parallel (AC 400V, 98% efficiency)

- Application: Peak shaving + backup for industrial plant

Results:

- Demand charges reduced by 35%

- PCS maintained <3% THD

- Zero communication errors (verified MODBUS handshake)

13. Common Compatibility Mistakes

- Ignoring voltage range mismatches:

Battery nominal 768V, PCS range 600–800V — fine.

But 512V battery won’t work with 600V min PCS input. - Assuming all MODBUS protocols are the same:

Register maps differ between battery brands; always test integration. - Undersizing PCS for peak load:

Always size PCS at 10–20% higher than rated discharge power to handle transient surges. - Neglecting cooling clearance:

Poor ventilation can lead to derating or shutdown in hot climates.

14. Future Trends in PCS Technology

- Wide-Bandgap Semiconductors (SiC, GaN):

Improve conversion efficiency by 1–2%. - AI-Based Control:

Predictive algorithms optimize charge/discharge scheduling. - Grid-Forming PCS:

Enable true islanded operation for microgrids. - Liquid-Cooled Modular PCS:

Increasing adoption in large-scale commercial and containerized ESS.

🚀 Expect PCS technology to shift from passive converters to active grid-supporting assets over the next 3–5 years.

Choosing a compatible PCS is crucial for the success of any commercial energy storage project.

It determines not just system efficiency, but also safety, scalability, and integration flexibility.

✅ Key Takeaways:

- Ensure voltage, protocol, and EMS compatibility.

- Select PCS with ≥97% efficiency and multi-protocol communication.

- Verify certification and thermal design for local conditions.

- Prefer modular, parallel-ready PCS for future expansion.

With the right PCS, commercial ESS systems can achieve optimal performance, reduced costs, and long-term reliability — turning energy storage from a technical challenge into a strategic business advantage.