Why Transport Protection Matters

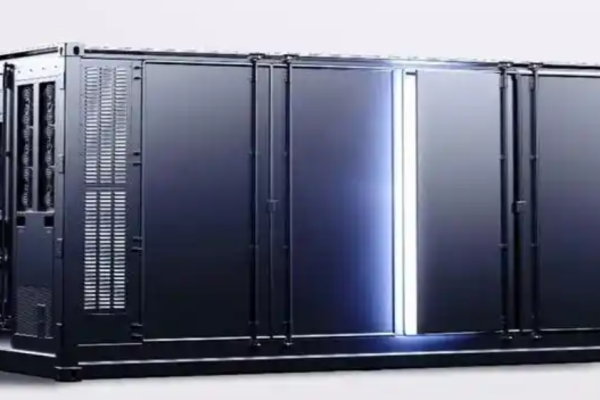

In energy storage system (ESS) exports, transportation is one of the highest-risk stages. Batteries and storage units are heavy, sensitive, and subject to strict safety regulations. Any damage during shipping not only leads to costly returns or warranty claims but also risks losing buyer trust. Preventing damage through proper planning, packaging, and logistics is therefore crucial.

1. Common Transport Risks for ESS Products

- Mechanical Shock and Vibration: Rough handling at ports, cranes, or forklifts can damage battery packs.

- Moisture and Humidity: Long sea voyages increase the risk of corrosion and short circuits.

- Temperature Extremes: High heat in containers or freezing conditions during transit can degrade cells.

- Improper Stacking: Overloading or poor container arrangement can crush modules.

- Regulatory Delays: Non-compliant packaging or labeling can result in extended storage, increasing risks.

2. Packaging Solutions to Minimize Damage

- Shock-Resistant Design: Use foam inserts, pallets with anti-vibration pads, and reinforced cartons.

- Moisture Protection: Seal units in plastic shrink-wrap and use desiccant packs inside packaging.

- Stacking Stability: Ensure crates are designed for vertical load bearing.

- Battery-Specific Containers: Use UN-certified packaging for lithium batteries.

- Environmental Monitoring: Temperature and humidity loggers can provide transparency for buyers.

Exporter Tip: Always align packaging with UN3480 / IMDG Code standards to avoid customs rejection.

3. Logistics Best Practices

- Choose Reliable Carriers: Partner with shipping companies experienced in hazardous goods.

- Container Preparation: Inspect containers for leaks, moisture, or damage before loading.

- Proper Weight Distribution: Heavy ESS cabinets at the bottom, lighter goods at the top.

- Cargo Securing: Use straps, airbags, and braces to prevent shifting.

- Transit Insurance: Comprehensive cargo insurance reduces financial risk.

4. Documentation and Compliance

- MSDS (Material Safety Data Sheet) must accompany shipments.

- Dangerous Goods Declaration ensures carriers handle the cargo properly.

- Clear Labeling with handling instructions reduces mishandling by workers.

- Export Certificates can help reduce inspection-related delays.

Exporter Tip: Ensure all documentation is correct to prevent long port storage, which increases the risk of damage.

5. Communication With Buyers

- Set Expectations Early: Explain packaging standards and protective measures.

- Share Tracking and Monitoring Data: Build trust by showing temperature/humidity logs.

- Offer Flexible Terms: If buyers want to arrange their own transport, clarify responsibilities for risks.

6. Cost-Benefit of Preventing Returns

- Direct Costs Saved: Fewer returns, warranty claims, and insurance disputes.

- Indirect Benefits: Improved buyer trust, repeat orders, and stronger long-term relationships.

- Competitive Advantage: Positioning as a reliable supplier with strong logistics capability.

Protection as a Selling Point

Preventing transport damage in ESS exports requires a combination of certified packaging, reliable logistics, compliance, and proactive buyer communication. By reducing the risk of damage and returns, exporters not only save costs but also strengthen their reputation as professional and trustworthy suppliers.