Why Customizable ESS Enclosures Matter for Scaling and Installation Flexibility

1. Introduction: The Rise of Modular Storage Solutions

As the energy storage market evolves from fixed utility-scale plants to flexible, small-to-medium energy storage systems (ESS), the role of modular storage cabinets has become increasingly important.

Whether for residential backup, commercial peak shaving, or rural microgrids, modular cabinet-based storage offers:

- Scalability (from 10kWh to 200kWh+)

- Customizable configurations

- Simplified installation and logistics

In this article, we’ll explore:

- What modular ESS cabinets are

- Key components and configuration strategies

- Why customization enables market competitiveness

- Design considerations for small project exporters

- SEO-friendly product positioning strategies

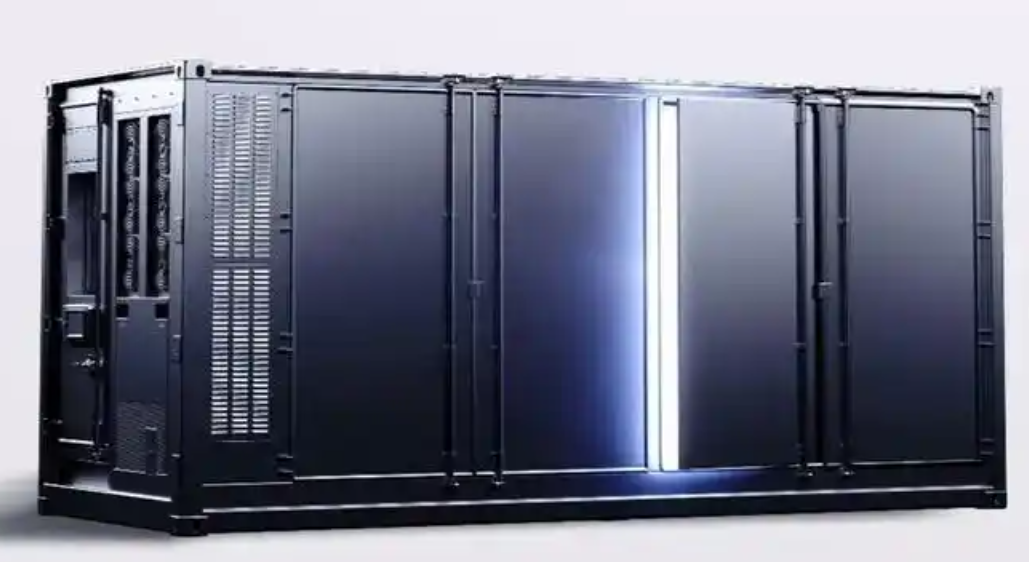

2. What Is a Modular Storage Cabinet in ESS?

A modular storage cabinet is a standardized battery enclosure that integrates:

- Battery packs (typically LFP modules)

- BMS (Battery Management System)

- Power wiring, fuses, breakers

- Optional integration with PCS (for all-in-one design)

These cabinets are designed to be:

- Pre-assembled or field-assembled

- Stackable or rack-mountable

- Flexible in terms of capacity, voltage, and layout

🧱 Think of them as the LEGO bricks of energy storage—flexible, reconfigurable, and easy to scale.

3. Why Modular Cabinets Matter for Small-to-Mid Projects

💡 1) Customer Demand is Fragmented

In global markets, demand varies greatly:

| Market Type | Typical Demand | Notes |

|---|---|---|

| Small businesses | 20–100kWh | Often need peak shaving |

| Households (off-grid) | 10–30kWh | Space-constrained |

| Farms, warehouses | 50–200kWh | Seasonal load patterns |

| Remote schools | 30–60kWh | Need easy transport/install |

Modular cabinets allow custom configuration per customer without redesigning the full system.

💡 2) Logistics Optimization

- Shippable in standard palletized or flat-pack formats

- Factory pre-wiring reduces site labor

- Can be split into multiple smaller shipments for phased deployment

4. Key Customization Options for Modular Cabinets

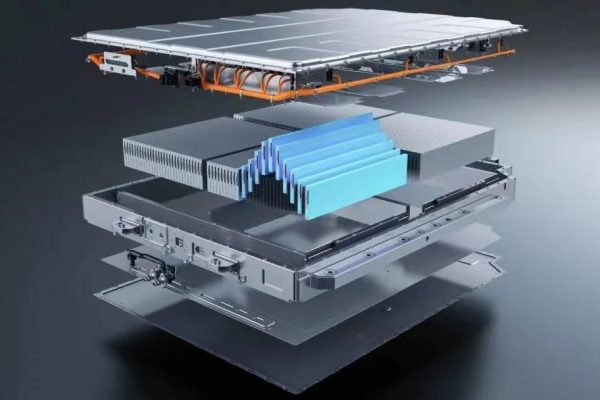

🧩 a. Battery Module Count & Arrangement

- Typical cabinet supports 4–12 LFP modules

- Stackable vertically, side-by-side, or in parallel cabinets

- Easy to configure 48V / 100V / 200V systems

🔧 b. Internal Wiring Design

- Customize for single-phase / three-phase output

- Include fuses, circuit breakers, DC switches

- Add busbars or terminal blocks as needed

⚙️ c. Enclosure Features

- IP Rating: IP20 (indoor) to IP55 (outdoor)

- Cooling method: Natural convection, fan-cooled, or HVAC

- Locking mechanisms and anti-theft designs for rural markets

🔋 d. Integration with Inverter or PCS

- Cabinets can be:

- Battery-only (external PCS required)

- All-in-one with inverter integrated on top

- Hybrid inverter brands (e.g., Growatt, Deye, GoodWe) can often be adapted

5. Typical Modular Cabinet Configurations

| Configuration Type | Application Scenario | Capacity Range |

|---|---|---|

| Vertical Stack (Indoor) | Small office / telecom | 10–30kWh |

| Parallel Side-by-Side | Factory peak shaving | 50–150kWh |

| Outdoor IP55 Wall Mount | Farm or island system | 15–60kWh |

| PCS-Integrated Cabinet | Turnkey C&I ESS | 100kWh+ |

🔧 Custom Quote Tip: Always confirm load type, daily cycles, and available space before proposing a cabinet layout.

6. How to Customize Modular Cabinets for Flexible Orders

As a technical foreign trade partner, your value lies in being agile and solution-driven. Here’s how to match cabinets to orders:

✔️ Step 1: Load Analysis

Ask your client:

- What equipment will be powered?

- Is the demand constant or peak-based?

- How many kWh/day is required?

✔️ Step 2: Battery Sizing

Use load data to recommend:

- Battery voltage (48V / 100V / 200V)

- Battery capacity (usable kWh)

- Cycle life requirement

✔️ Step 3: Cabinet Configuration

Based on:

- Space (indoor/outdoor)

- Local IP rating needs

- Expansion requirement (future growth)

✔️ Step 4: Custom Features

- Include optional EMS ports, LCD screens, or remote monitoring

- Offer branding, labeling, or color customization

7. Advantages of Offering Modular Storage as a Technical Supplier

| Advantage | How It Helps Your Customers |

|---|---|

| Fast Lead Time | Stocked parts + flexible config = faster delivery |

| Scalable Pricing | Buy only what’s needed today, expand later |

| Simplified Logistics | Ship in 20′ or 40′ containers with optimized layout |

| Customization Without MOQ | Small batch support wins trust in early stage |

| Clear Project Proposals | Pre-draw system layout & connection schemes |

🔗 Bonus Tip: Offer CAD drawings, load curve analysis, and system schematics to win trust.

8. Internal Link Suggestions

Here are internal blog articles you should link from this post:

- 👉 How to Match a Battery Pack with a Hybrid Inverter

- 👉 Typical Configurations for Residential PV + Storage Systems

- 👉 How to Design ESS for Peak Shaving and Load Shifting

9. Conclusion: Modular = Competitive

In emerging PV + storage markets, flexibility and fast response matter more than rigid standardization.

By offering modular battery storage cabinets with customized configurations, you’re:

- Solving customers’ real-world site limitations

- Providing tailored energy solutions without high MOQs

- Becoming a strategic technical partner—not just a supplier

🚀 Modular is not just a design. It’s a sales advantage.