⚙️ Why Understanding Load Profiles Is Crucial in C&I Energy Storage Projects

In Commercial and Industrial (C&I) energy applications, understanding the load profile is the foundation of any successful energy storage system (ESS) design. Unlike residential usage patterns, C&I facilities often exhibit sharp demand peaks, equipment-driven loads, and complex operating schedules.

A properly designed ESS can maximize self-consumption, enable peak shaving, participate in demand response, and reduce time-of-use (TOU) charges—but only if the system matches the real-world load characteristics.

In this article, we’ll explore typical load profiles in various C&I sectors, and how they influence system design, sizing, and technology selection for PV + battery or standalone ESS projects.

🏭 Key Types of Load Profiles in C&I Applications

C&I load curves vary depending on business type, operations, climate, and energy-intensive equipment. Here are the five most common types:

1. Flat Continuous Load – 24/7 Operations

Typical sectors: Data centers, cold storage, hospitals, server farms

Features:

- High, consistent load day and night

- Minimal variation; predictable daily curve

- Critical loads (often require backup systems)

Implications:

- PV self-consumption is high, as solar offsets constant base load

- Battery use: Mainly for backup and demand charge reduction

2. Daytime Peak Load – Office Buildings / Retail

Typical sectors: Offices, supermarkets, schools

Features:

- Sharp rise in load from 8 am to 6 pm

- Peak aligns with solar generation curve

- Drops in evenings and weekends

Implications:

- Ideal for PV + battery self-consumption

- Battery can be smaller; mainly supports TOU shifting or short-term grid support

3. Evening/Night Peak Load – Hospitality / Entertainment

Typical sectors: Hotels, restaurants, event venues

Features:

- Peak demand starts after sunset

- Lighting, HVAC, kitchens, elevators peak from 6–11 pm

- Weekend activity more intense

Implications:

- PV generation doesn’t align with peak

- Battery plays a critical role, discharging from sunset to night

- Larger battery banks needed for full coverage

4. Double Peak – Manufacturing with Split Shifts

Typical sectors: Industrial factories, textile mills, electronics

Features:

- Early morning peak (7–11 am)

- Mid-afternoon to early evening peak (2–7 pm)

- Heavy machinery, HVAC loads, motors

Implications:

- Requires sophisticated EMS to predict and flatten peaks

- Suitable for peak shaving + time-of-use optimization

- Battery + EMS coordination crucial to ROI

5. Intermittent / Batch Load – Agro Processing, Welding, Printing

Typical sectors: Metal fabrication, plastic molding, food packaging

Features:

- Load spikes tied to batch production cycles

- Irregular or seasonal usage

- May operate only certain days of the week

Implications:

- Requires demand forecasting

- Energy storage design must factor idle time vs. peak burst

- Ideal candidate for energy arbitration + backup

🔍 Analyzing a Real C&I Load Curve Example

Let’s take a look at a light industrial building:

| Time | Load (kW) |

|---|---|

| 6–8 am | 50 |

| 8–12 pm | 120 |

| 12–2 pm | 90 |

| 2–6 pm | 140 |

| 6–10 pm | 60 |

| 10–6 am | 20 |

Insights:

- Morning & afternoon peaks

- High potential for PV during 10am–4pm

- Battery needed for 2–6pm peak shaving

- Consider hybrid inverter with peak demand control

📊 Designing ESS Around Load Profile Types

| Load Profile | PV Role | Battery Role | EMS Role | System Priority |

|---|---|---|---|---|

| Flat Load | High offset | Backup, grid response | Grid balancing | Reliability |

| Daytime Peak | Full offset | TOU shifting | Simple scheduling | Cost saving |

| Night Peak | Minimal | Primary discharge | Load prioritization | Energy availability |

| Double Peak | Partial | Peak shaving | Advanced EMS | Grid stability |

| Batch Load | Variable | Fast response | AI/demand prediction | Energy arbitrage |

🔧 Matching Inverter and Battery to Load Curve

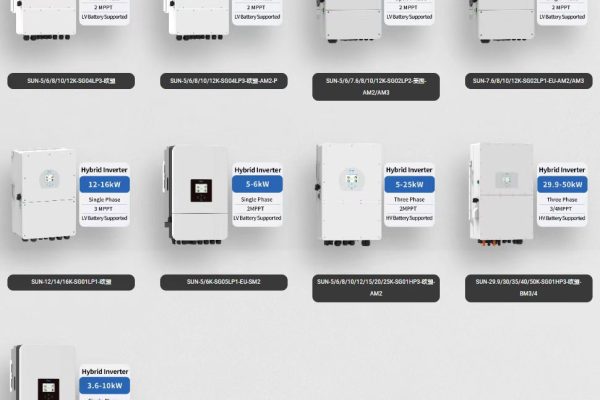

Inverter:

- Must support multiple operating modes (on-grid/off-grid/hybrid)

- Should allow custom load scheduling

- Consider multiple MPPTs if rooftop PV is split

- EPS or backup mode is a must for critical loads

See our guide: 👉 How to Choose a Hybrid Inverter for Small-Scale PV Projects

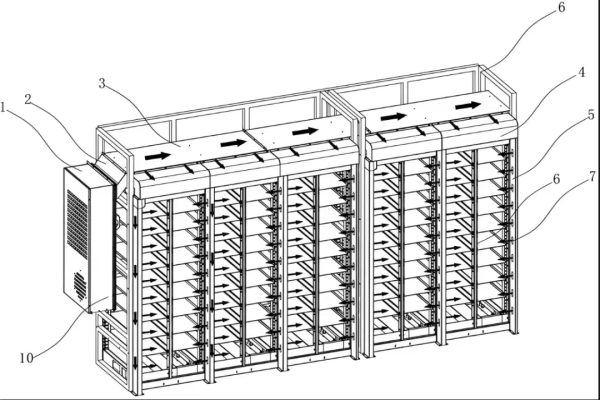

Battery:

- High cycle life (5000–8000 cycles) for daily use

- Fast charge/discharge for load peaks

- Scalable capacity (rack/stack type)

- Check battery C-rate compatibility with load spikes

🧠 How EMS Enhances Load Matching

Modern C&I EMS platforms offer:

- Load forecasting based on historical data

- Dynamic load shedding in emergency

- TOU optimization (charge during off-peak, discharge during peak)

- Integration with diesel genset / grid curtailment signals

Investing in EMS is critical to extracting full economic value from your C&I system.

🧾 Why Load Profile Defines Your ROI Model

Let’s compare two facilities:

| Factory A | Hotel B |

|---|---|

| 8am–6pm operation | 5pm–11pm peak |

| High solar overlap | Solar mismatch |

| PV-heavy system | Battery-heavy system |

| Fast ROI (~4 years) | Slower ROI (~6–8 years) |

Your load curve determines system type, sizing, and financial return.

🧭 Final Thoughts

C&I load profiles are more than just a curve—they’re a blueprint for your entire energy strategy.

Whether you are an EPC, distributor, or end-user planning a commercial solar + storage project, investing the time to understand the load structure will save you time, cost, and complexity down the road.

💬 Need Help Analyzing Your Facility’s Load Curve?

We support integrators and facility managers with:

- 📈 Load profile analysis

- 🧮 System design recommendations

- 📦 Battery + inverter matching

- ⚡ Rapid-response BOM quotes (small and mid-scale welcome)